Our History

Yamamoto: 100 Years of History

1918

Established. Began manufacturing and selling mulberry cutting machines for silk production.

1946

Created a cylinder-type machine for cutting straw and wood. Recognized for our contributions to livestock farmers.

1966

Became the leading manufacturer of grain dryers.

Produced batch-type circulating grain dryers with a capacity of 900–30,000 kg.

1987

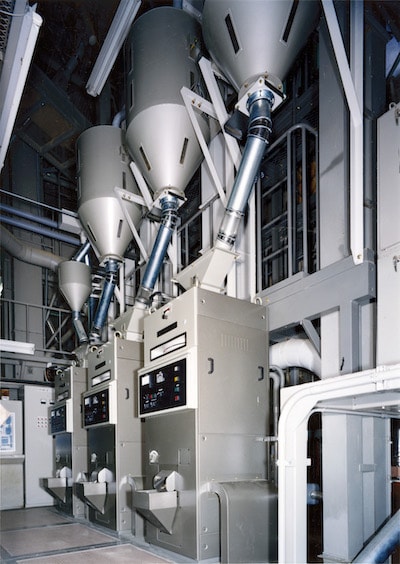

Began selling a combination-type rice milling machine combining abrasive and friction functions with 600–8,000 kg/hour capacity.

1990

Increased our focus on environmental sustainability, developing the “High Melter” Styrofoam melter and Pellet Stove.

1993

A national dealer meeting was held in Japan to commemorate the company’s 75th anniversary.

Entered the country elevator business with Stir-Drying Depot, a cumulative-stir and drying storage system.

1998

Completed our first rice milling model plant in Hebei Province, China.

A ceremony was held to commemorate the company’s 80th anniversary.

2008

Celebrated the 90th anniversary of our founding. Established Yamamoto Machine (Suzhou) Co., Ltd. and began production in China.

2013

Opened Suzhou Mizuho Machinery Co., Ltd. Technical alliance with Fowler Westrup (India) in the field of rice milling.

2018

Celebrated the 100th anniversary of our founding. Released two machines; the RE-E2000, a large styrofoam volume reduction machine, and the “OU” wood pellet stove.

2019

Refreshed our corporate identity with a new logo, logotype, and uniform. Released the RE-E2000, a large EPS volume reduction machine.

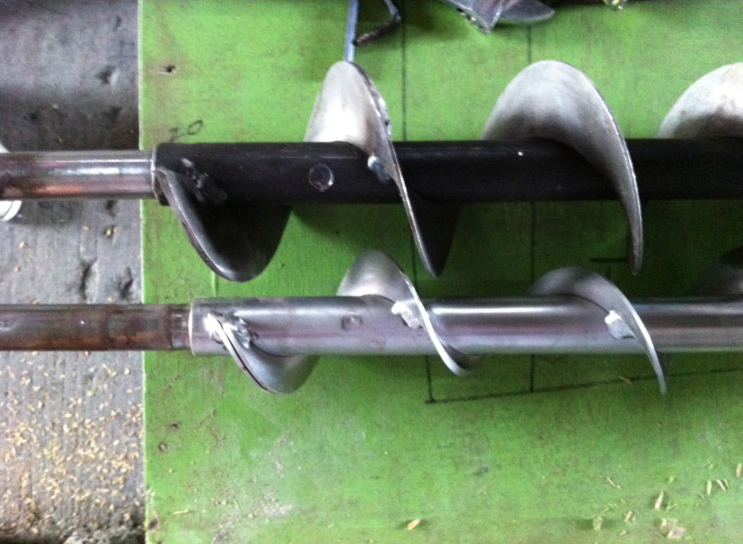

Trial and Error in the Long-Grain Market

The requirements for equipment in the long-grain market are very different from that of the short-grain market that we have experienced for over a century in Japan.

We first started selling dryers for long grains in the Philippines in 2011. We had failed to calibrate the durability of our components to the different usage conditions.

This led to many instances where we could not demonstrate a high milling recovery rate and low power consumption.

We learned the hard way that our knowledge of the drying process for long grains was insufficient, which we deeply regret.

Learning from these mistakes, we have since taken the time to regularly visit our customers to understand their usage conditions, grain characteristics, and the ongoing challenges they face.

The insights gained from listening to our customers have since been reflected in our products. We are happy to say that our customers in recent years have given us very favorable feedback on the performance, reliability, and usability of our machines.