Rice Milling Machines for Long Grain

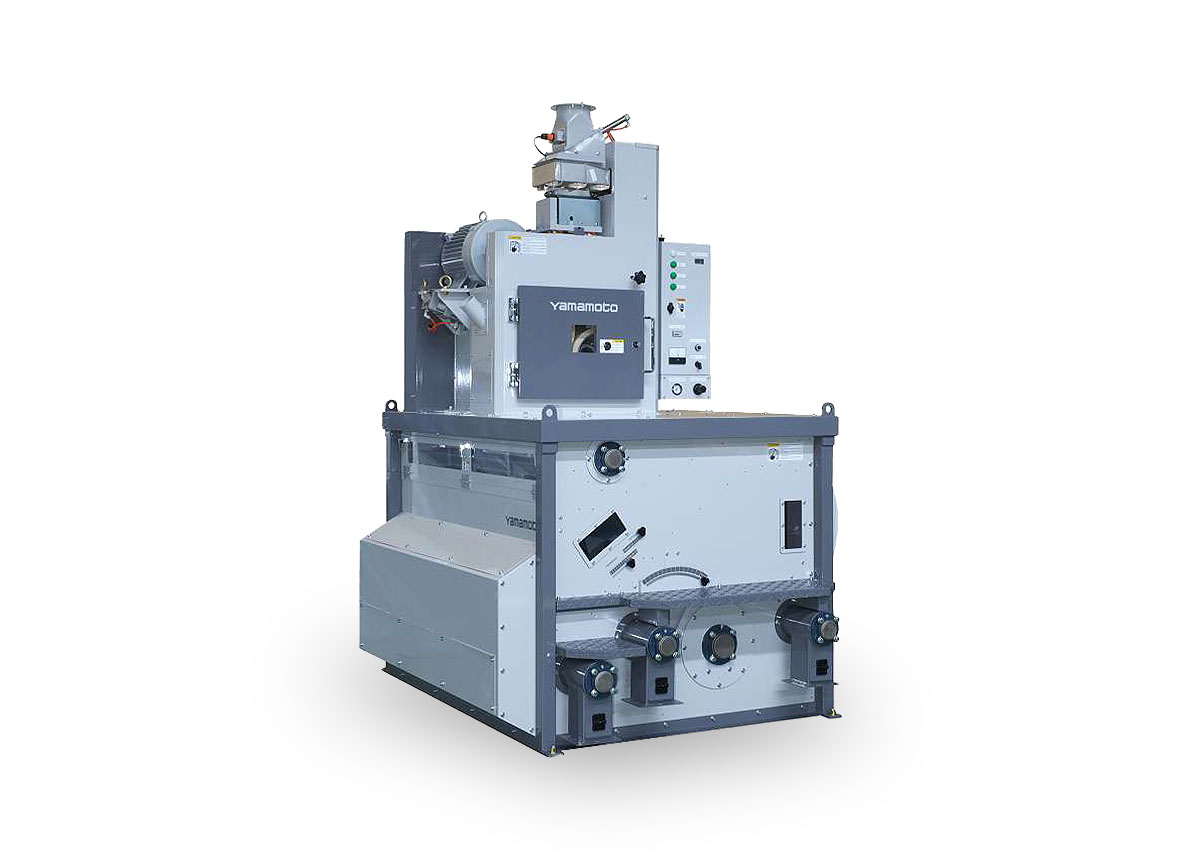

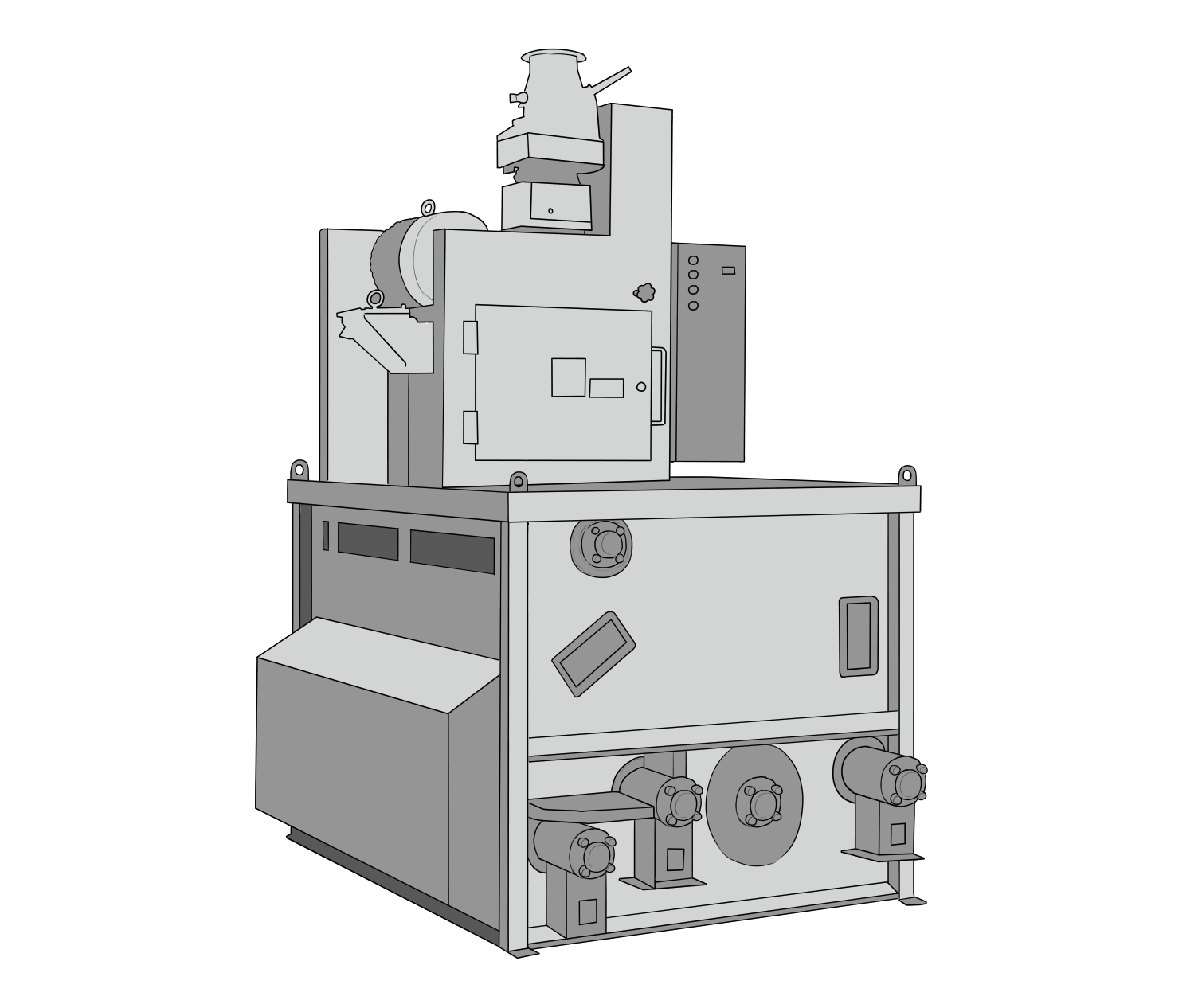

Paddy Husker

The electromagnetic feeder and chute provide a stable supply of paddy, and the inclined rolls offer high efficiency.

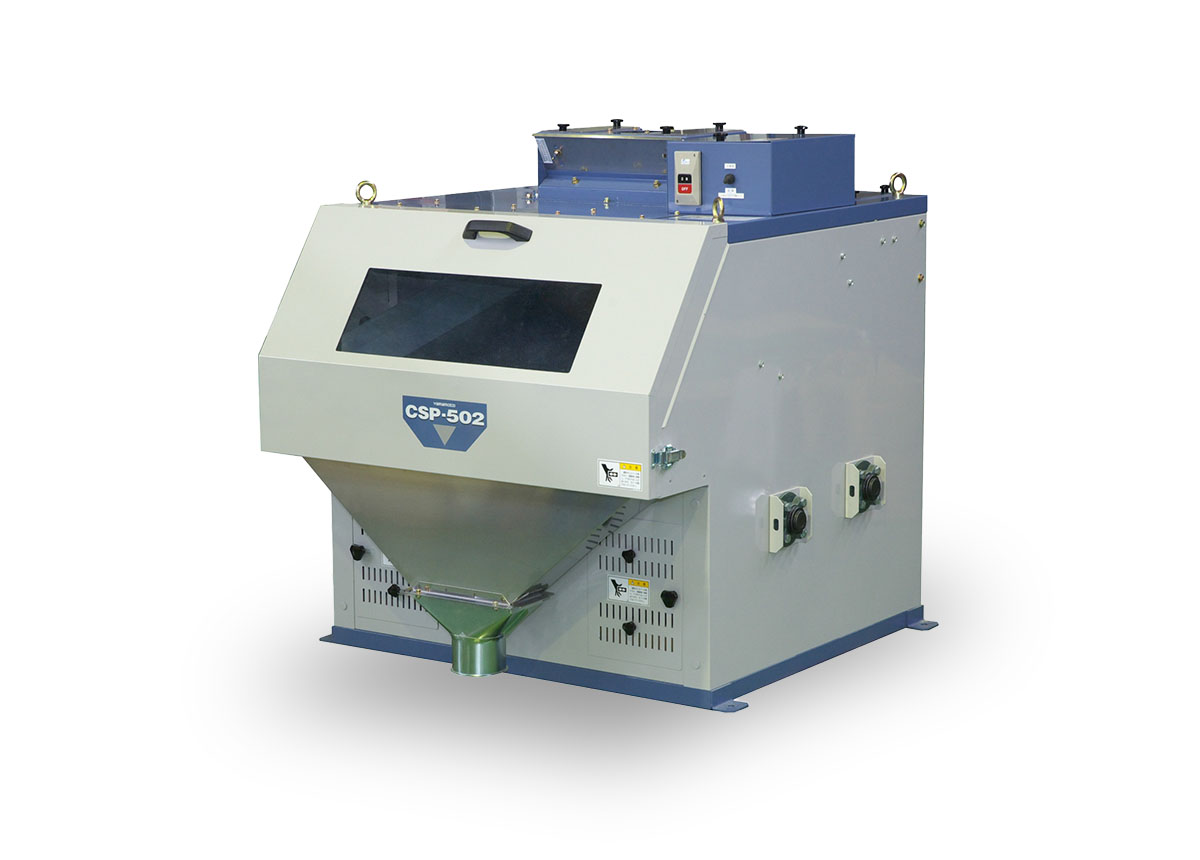

Paddy Separator

By adjusting the horizontal and vertical inclinations, sorting work can be performed according to the variety and condition of the paddy, and the performance will remain stable.

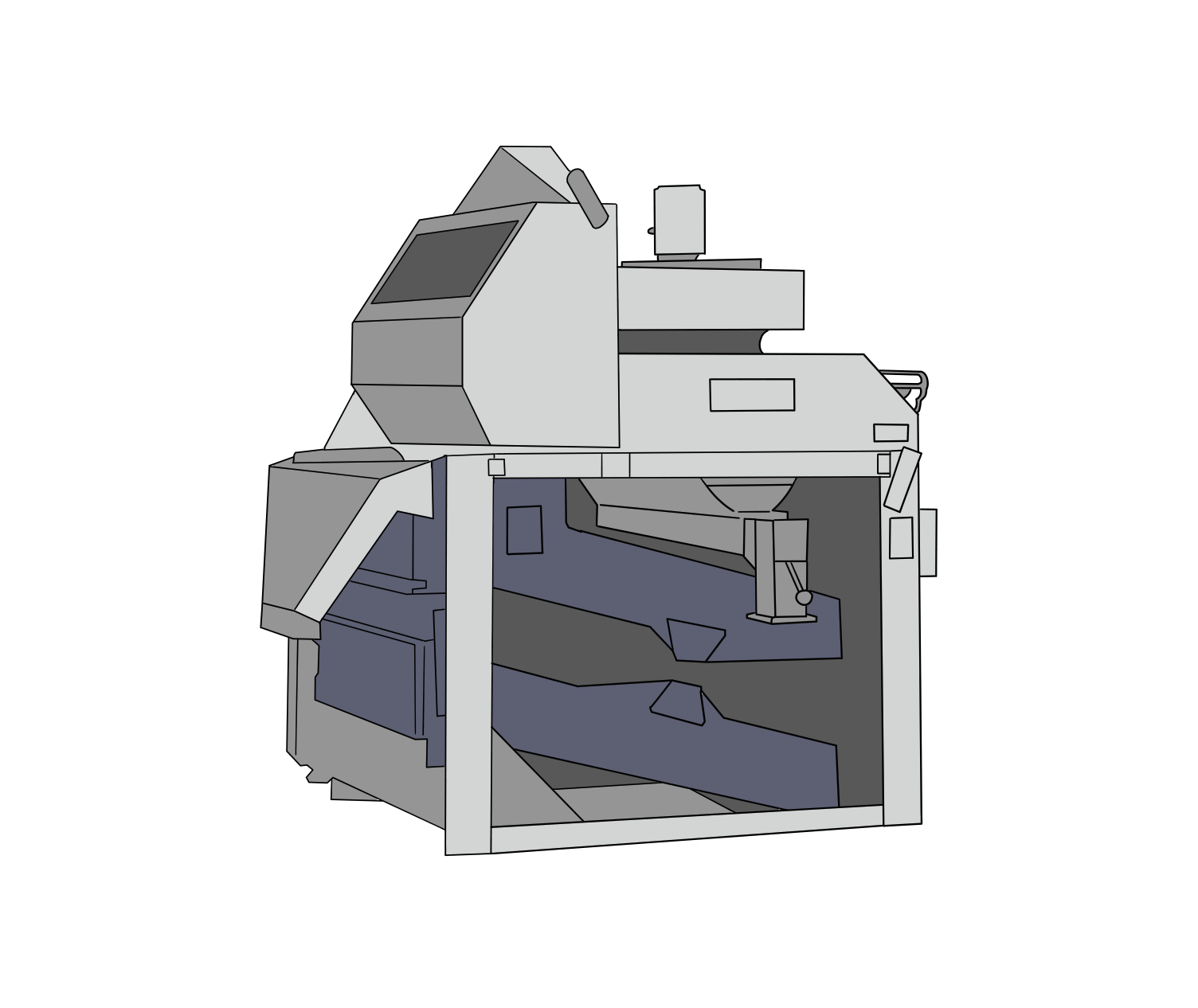

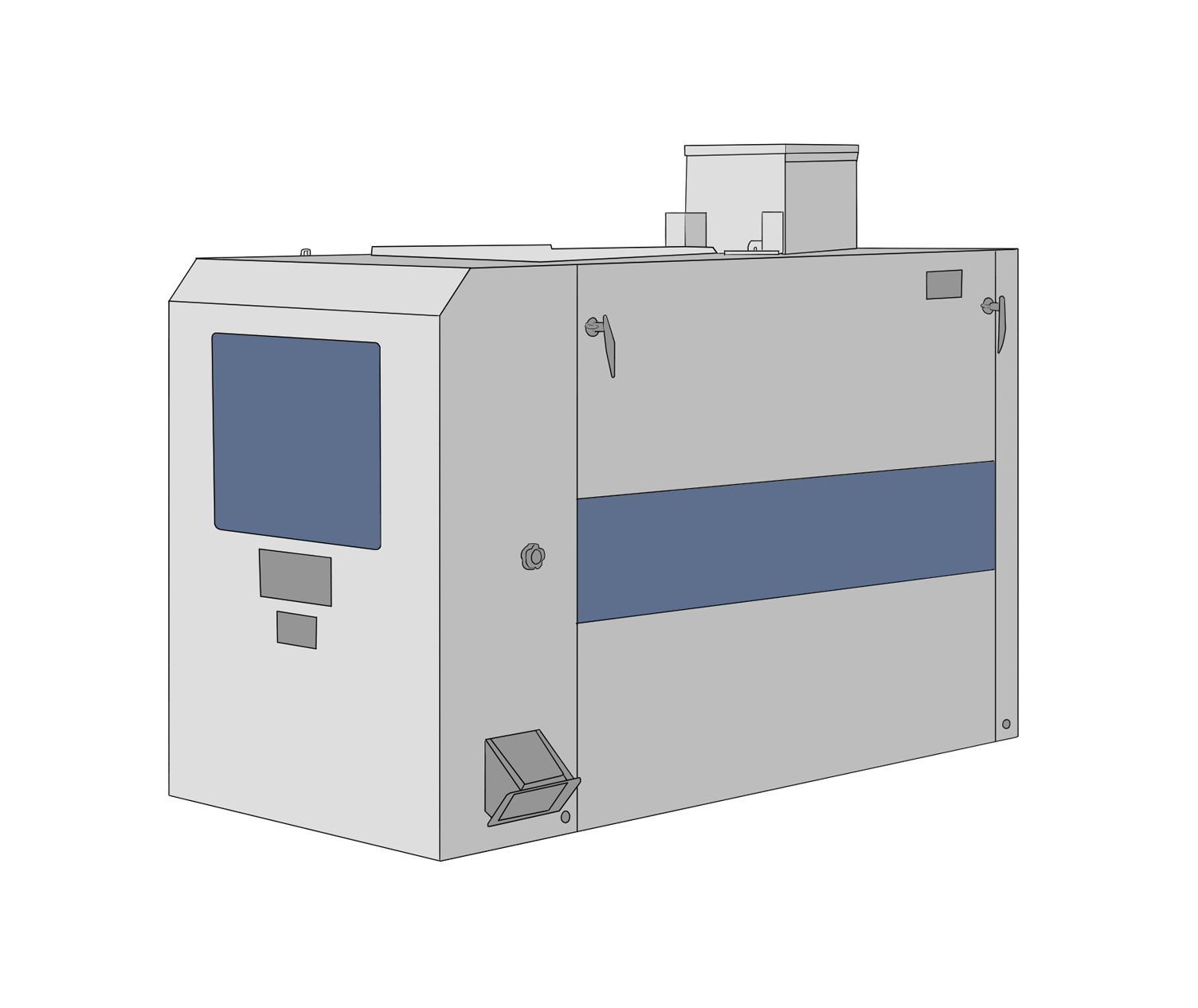

De-Stoner

Primary and secondary sorting decks work to minimize the amount of brown rice in the discharged stones, thereby maximizing the milling recovery rate.

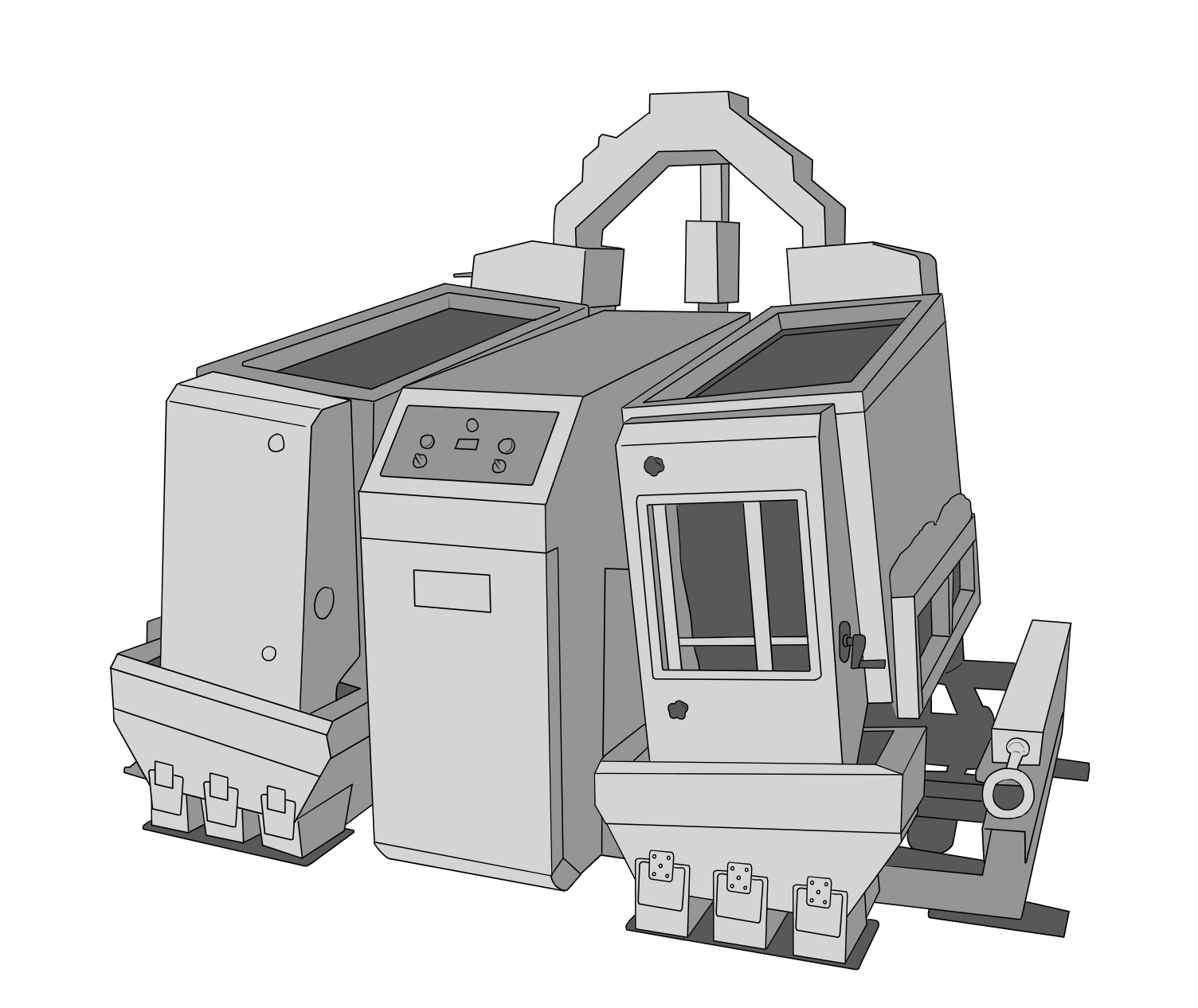

Grading Sifter

Features highly efficient and accurate separation technology. Basic maintenance can be performed without tools, making daily operation easy.

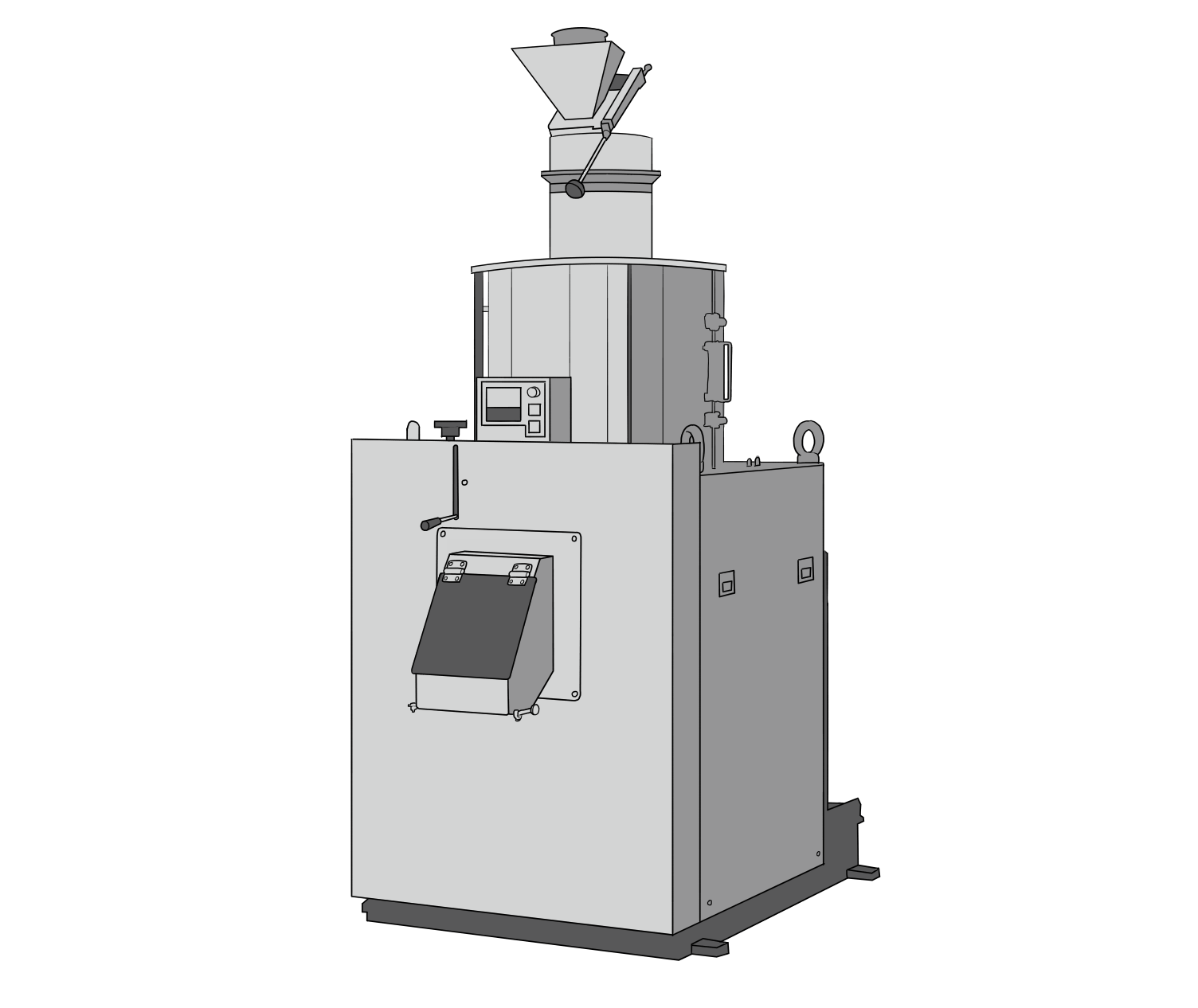

Vertical Friction Polisher

The Vertical Friction Polisher applies uniform pressure while vertically aligning the rice with gravity, resulting in a higher milling recovery rate.

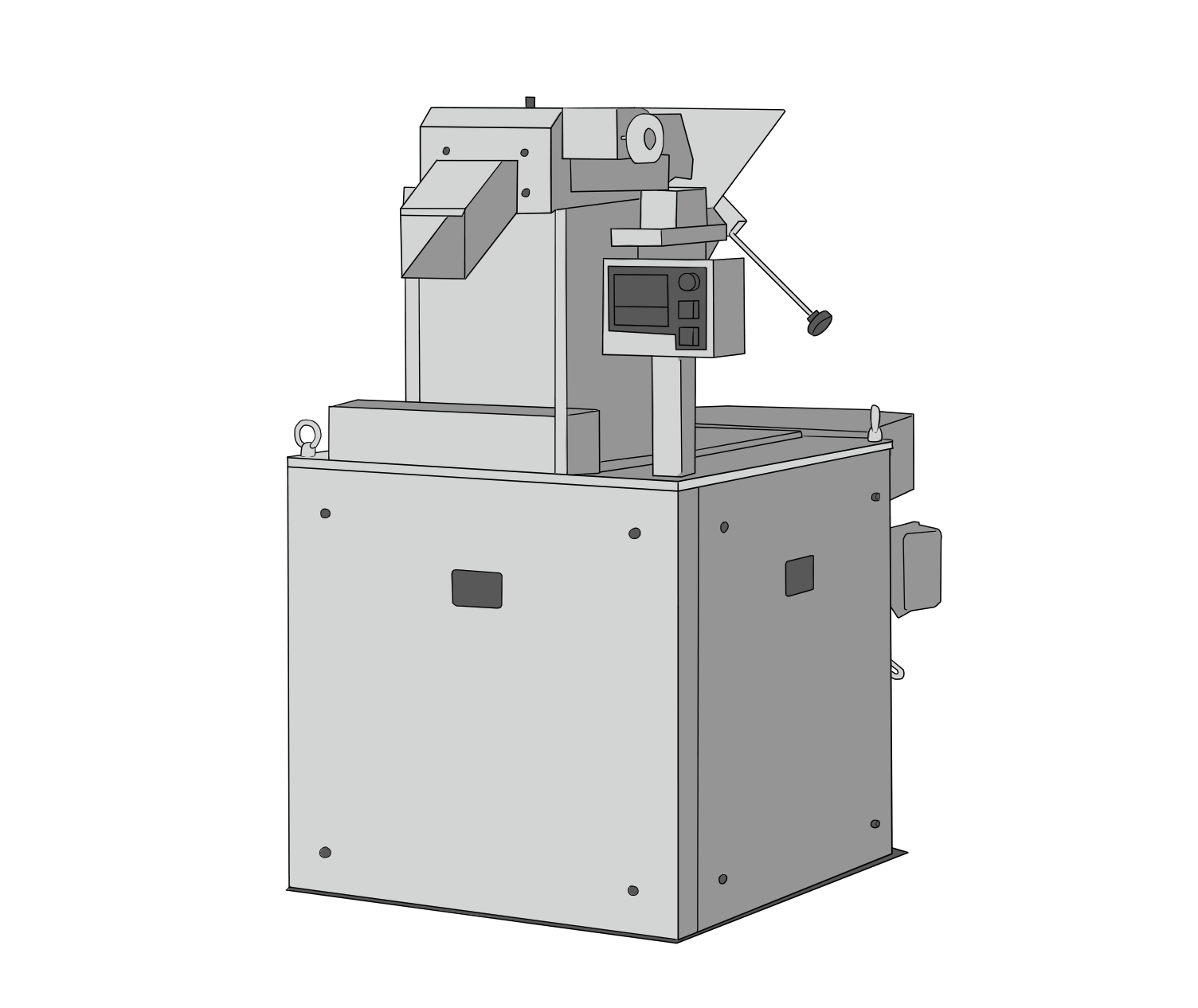

Abrasive Whitener

A unique whitener scratches the surface of brown rice instead of grinding it to improve the friction coefficient of the Vertical Friction Polisher in the following process. This results in a higher milling recovery rate of the whole process.

- Maximizing Rice Milling Plant Profitability

-

We sometimes receive inquiries from customers who are disappointed that their rice milling recovery rate and operational efficiency have not improved as expected even after installing sophisticated rice milling equipment.

First, you need to find out which part of the rice milling process is the bottleneck. Often the equipment is not connected correctly, or there is a mix of products from multiple companies on the rice milling line, resulting in a large amount of broken rice.

To maximize profits, the entire operation must be designed scientifically, considering the rice’s character and the processing conditions. This planning should be completed before installing any equipment. However, it requires many years of experience and deep expertise.

Building on our many years of experience providing a wide range of equipment for rice milling, we can offer comprehensive plant optimization consulting, including the following.

- Rice milling plant design.

- Suggestions for minimizing running costs and improving maintenance efficiency.

- Offering ways to improve operational efficiency with digital technology.

- Advice on how to improve an existing plant’s ability to meet market trends.

- Advice from rice milling professionals.

Also, assembling a unified rice milling line with our equipment will enable high-quality rice production with a high yield while minimizing power and labor costs.

If you are thinking of building or reviewing a rice milling plant, don’t hesitate to contact us.

- Best Practices for Productivity and Quality Improvement

-

Without proper drying, the rice will crack during the drying process. In such a case, no matter how much effort is put into the rice mill, the milling recovery rate will not increase.

Our Solution

The best way to achieve higher quality rice, higher milling recovery rates, lower costs, and stable production is to own and manage the drying and milling machines.

We are one of the few manufacturers with expertise in both drying and milling rice. Let us support the growth of your rice production business with our machines.

Contact us today to discuss your needs.

Why Choose Yamamoto Rice Milling Machines?

Comprehensive Rice Milling Process Optimization

If you are planning a new rice milling plant, we can design it with you from scratch. We will recommend the most suitable machines and configurations to maximize productivity.

Maximizing Milling Recovery Rate

For more than ten years, we have conducted research and testing to maximize the profit of rice mills. A significant focus has been ensuring that long grain paddy and rice are not overloaded and are milled evenly.

To achieve high recovery rate with long grain, which even the slightest impact can break, we propose the appropriate rice milling line for each customer’s situation.

High-Quality Rice Milling at Low Cost

Each of our rice milling machines is designed to maximize the milling recovery rate and quality while minimizing electricity costs. For example, our Vertical Friction Polisher uses gravity in the rice polishing process, dramatically reducing the need for electricity.

Labor-Saving through Simple Operation and Structure

Our machines are designed for ease of use. All an operator has to do is switch on the device and set the resistance value. It will then run reliably without the need for close supervision or additional calibration.

Since only a few people are needed to complete the milling process, labor costs are reduced. Furthermore, the system does require a high level of skill or technical knowledge to operate, minimizing the need for extended staff training and supervision.

Customer Stories

Product Tours: See for Yourselves

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Boost Your Profits

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.

Sustainability

The Sustainable Development Goals (SDGs), also known as the Global Goals, were adopted by the United Nations in 2015 as a universal call to action to end poverty, protect the planet, and ensure that by 2030 all people enjoy peace and prosperity.

At Yamamoto, we are fully committed to doing our part. In particular, we are working towards contributing to the following SDGs.

![]()

![]()

![]()

![]()

Goal 2 Zero Hunger

- Improve local economic development through improved rice production.

- Reduce food loss in the drying and milling process.

- Enable mass production to cope with population growth.