Vertical Friction Polisher

XPF-50/60

XPF-50D/50M

The Vertical Friction Polisher applies uniform pressure while vertically aligning the rice with gravity, resulting in a higher milling recovery rate.

Maintenance & Troubleshooting:

Product Features

High Milling Recovery Rate

Our XPF-50/60 mills the rice evenly without excessive power because the input rice is already ground uniformly by the XPA-25 in the previous milling process. Consequently, the milled-rice recovery rate is higher by 0.5 to 1.0%*.

* As per our internal tests.

Low Milling Temperatures

Since the rice flows vertically down during milling, the pressure inside the milling chamber becomes even. This results in significantly lower temperatures compared with traditional machines.

Optimal Residual Grain Removal

Residual grain can easily be discharged by simply moving the exhaust lever manually.

Easy maintenance

Because of its simple structure, machine parts can be easily replaced. The XPF-50’s structure follows the same simplified design approach as our XPA-25. Thus, maintenance tasks are quicker and easier.

Dry & Mist Type Polisher Options

We offer two innovative approaches to achieving higher quality white rice.

- Vertical Friction Mist Polisher: Our XPF-50M machine features a mist treatment that sprays water on the surface of white rice to whiten its appearance.

- Vertical Friction Dry Polisher: Our XPF-50D machine provides a polishing treatment that removes residual bran without using water.

Customer Stories

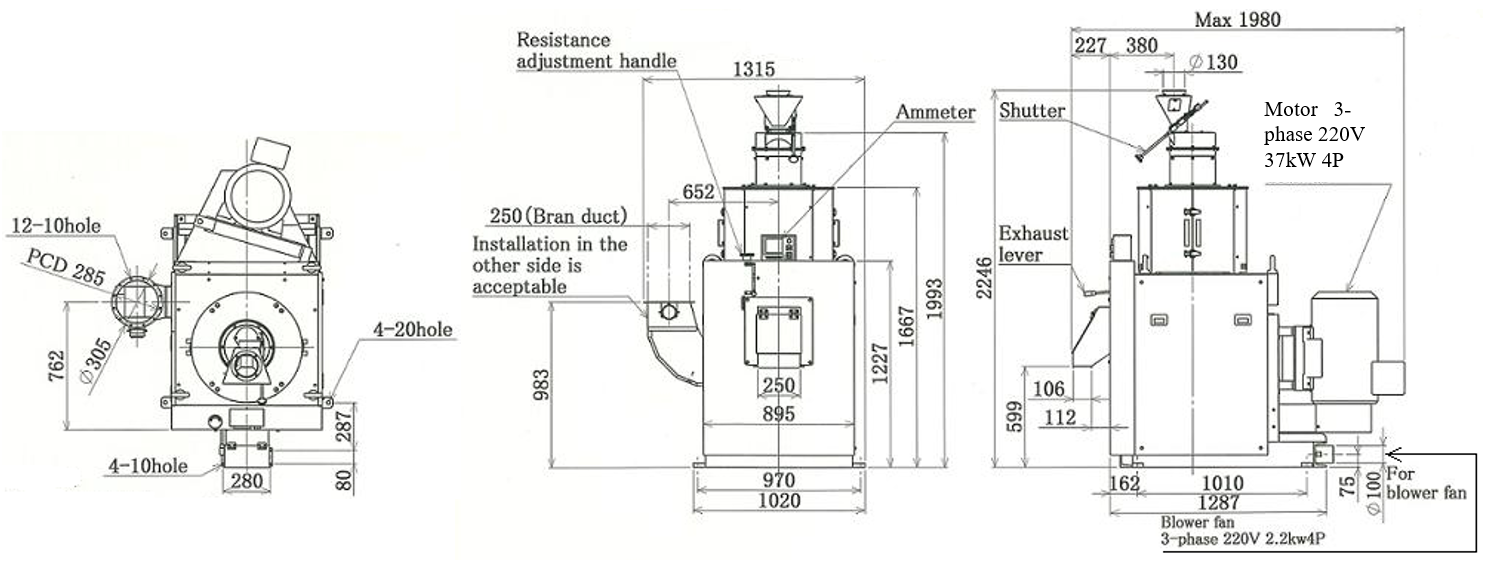

Specifications

| Model Name | XPF-50/60 | ||

|---|---|---|---|

| Input brown rice capacity | t/h | 2 ~ 5 | |

| Demensions | Length | mm | 1,980 |

| Width | mm | 1,315 | |

| Height | mm | 2,246 | |

| Net Weight | kg | 1,500 | |

| Height of milled rice outlet | mm | 599 | |

| Necessary Power | kW | 3-phase 200 / 220 / 380 / 420 / 460V |

|

| Motor | kW | 39.2(XPF-50) / 47.2(XPF-60) | |

| Required Air volume | m3/min | 50 | |

| Required static pressure | kpa | more than 2 | |

* Precise capacity depends on brown rice variety and quality of input.

* We are continuously innovating. Therefore specifications and dimensions are subject to change.

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- Which machine should I use to mill long grain rice?

-

Selecting the most suitable machine depends on the variety of long grain, drying method, and required capacity. Please feel free to contact us to confirm the necessary information and make suggestions.

- How long will consumable parts keep in stock?

-

For each of our machines, we continue to offer consumable parts for ten years after its production is discontinued.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

Product Tours and Consulting

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.