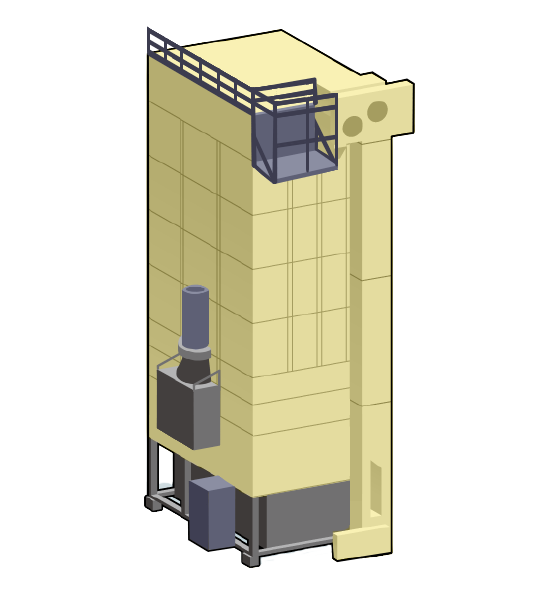

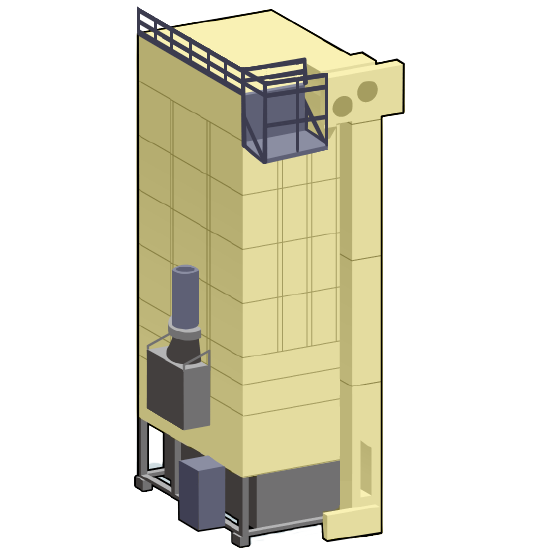

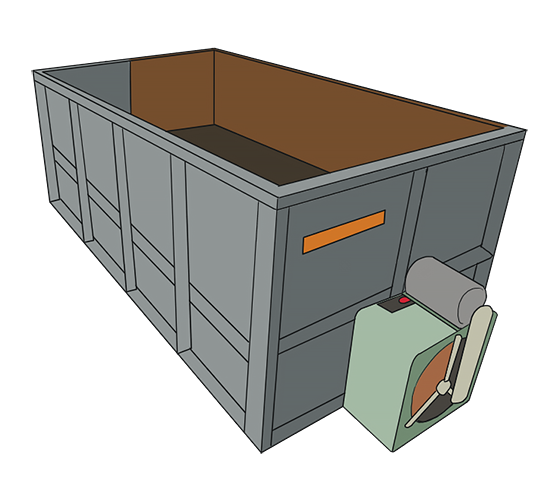

NEW MODELSmart Grain Dryers MASTER

- Evolution of Smart Grain Dryers MASTER

-

New Features & Modifications

Durability Improvements

- More increased wear resistance of drying chamber, moisture meter, and bucket elevator

Reliability & Stability Improvements

- New designed diagonal blowers

- Adoption of motor direct drive for bucket elevator

Support for Various Heat Sources

- Husk furnace, diesel burner, LNG/LPG burner, steam

Adapted stately dark blue color to the bottom part

- Why Smart Rice Producers Use Dryers

-

Challenges with Sun Drying

Drying paddy in the sun usually takes more than one day. At night, they put the paddy back into the bags, and the next day, spread it out on the ground again. This process has to be repeated.

It is a time-consuming and labor-intensive process. Rain may result in rotting rice if dry conditions do not return soon enough. Hot and sunny weather may result in rice cracking.

Installing a Yamamoto dryer solves these problems. Drying is fast and efficient regardless of weather conditions. The processing volume can be increased. Moisture content will be consistent, allowing for the production of higher-quality, higher-milling recovery rice.

- Grain Dryers: Batch Circulating vs. Flatbed

-

Learn the difference between two types of rice grain drying machines:

Dryer Type

Structure

Pros

Cons

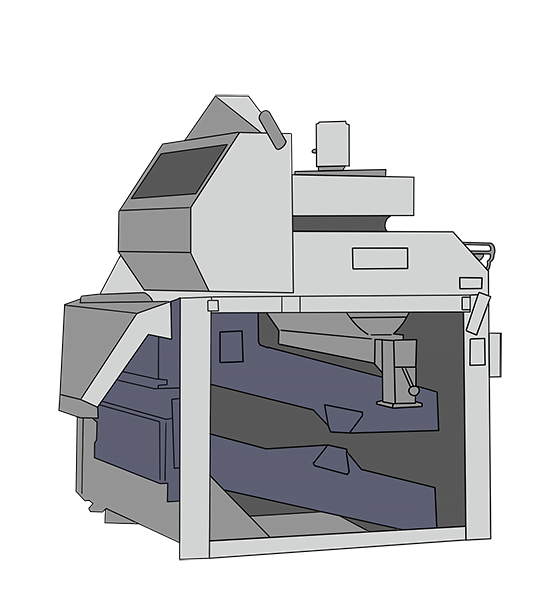

Batch Circulating

Structure

The rice is put in from the top and moved to the bottom while drying and then transported from the bottom to the top again and put in repeatedly.

Pros

Less unevenness in drying and high drying efficiency.

Cons

They are often bulky and expensive.

Flatbed

Structure

The rice is piled on the perforated steel plate of the drying box so that it is flat, and hot air is sent from the bottom.

Pros

Usually inexpensive due to their simple and compact mechanisms.

Cons

Since the rice does not circulate, uneven drying occurs; reducing the quality and milling recovery rate.

Conclusion

We recommend the batch circulating type of grain dryer. By circulating the paddy, the drying and tempering process is repeated, and the moisture is removed evenly. The system automatically dries to the exact moisture content without stressing the rice. This prevents over-drying or under-drying.

- Best Practices for Productivity and Quality Improvement

-

Without proper drying, the rice will crack during the drying process. In such a case, no matter how much effort is put into the rice mill, the milling recovery rate will not increase.

Our Solution

The best way to achieve higher quality rice, higher milling recovery rates, lower costs, and stable production is to own and manage the drying and milling machines.

We are one of the few manufacturers with expertise in both drying and milling rice. Let us support the growth of your rice production business with our machines.

Contact us today to discuss your needs.

Why Choose Yamamoto Circulating Dryer?

Increased Milling Recovery Rate

Once the amount of grain and the target moisture content are set, the system automatically controls the drying temperature and circulation speed to the optimum level. This prevents cracks from occurring.

- Automatically calculate the hot air temperature and circulation speed to match the appropriate speed.

- Ideal balance between drying and tempering processes. Even if the moisture content varies, it can be dried to uniform moisture content.

Higher Quality Rice

Produces beautiful rice without racks and uneven moisture content.

- Equipped with a high-precision moisture sensor to ensure stable finished moisture content.

- Uses a rotating equalization system and shutter-drum circulation to ensure even and uniform drying.

Higher Speed & Drying Capacity

The large drying chamber and optimum hot air temperature control maximize drying performance, resulting in higher volumes of rice being dried faster.

Labor-Saving

The easy-to-use control panel and automation of the drying time process reduce operator work time and training cost. The top of the dryer is equipped with a no-residue mechanism. Thus, all residual cleaning after use can be completed by an operator standing on the ground.

Efficient Management

Drying history data can be saved to an SD card, enabling operators to analyze it and find ways to improve efficiency. Furthermore, the automatic control makes it possible for anyone to perform high-precision drying without relying on the experience or sense of the operator.

Customer Stories

Product Tours: See for Yourselves

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Boost Your Profits

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.

Sustainability

The Sustainable Development Goals (SDGs), also known as the Global Goals, were adopted by the United Nations in 2015 as a universal call to action to end poverty, protect the planet, and ensure that by 2030 all people enjoy peace and prosperity.

At Yamamoto, we are fully committed to doing our part. In particular, we are working towards contributing to the following SDGs.

![]()

![]()

![]()

![]()

Goal 2 Zero Hunger

- Improve local economic development through improved rice production.

- Reduce food loss in the drying and milling process.

- Enable mass production to cope with population growth.