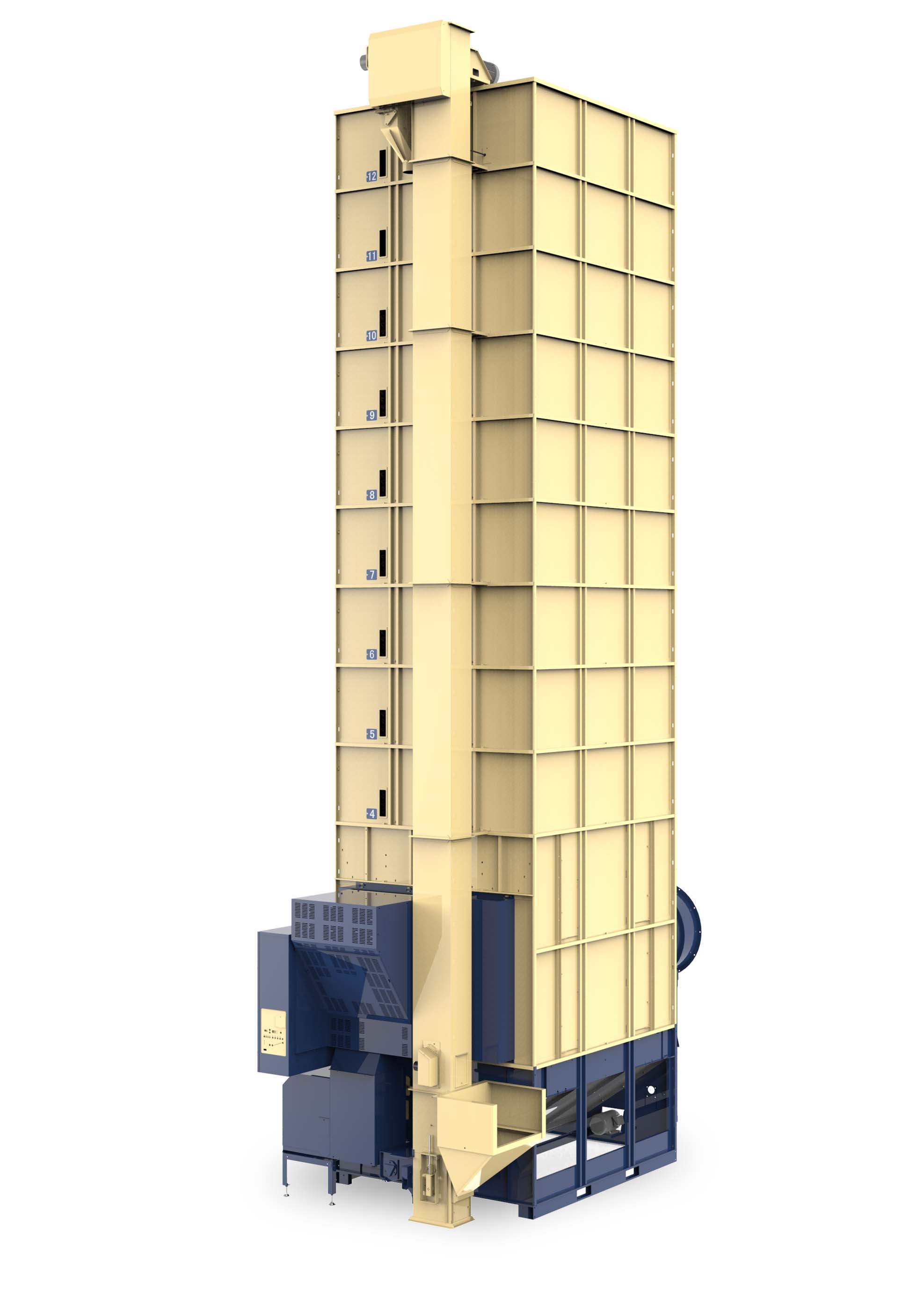

NEW MODELSmart Grain Dryers MASTER

12t Series

12t series can dry 8.4 – 12 tons of paddy with higher milling recovery rate while using less energy than conventional dryers

Product Features

Operation Panel

- User-friendly control panel with large letters and clear display.

- The hot air temperature and circulation speed are computed automatically by the loaded amount, outside temperature, and moisture value.

- The process proceeds flawlessly with optimal drying conditions.

Heat Controller*

- A suction blower mixes the hot air with outside air and supplies stable heat to the dryer.

- The hot air temperature is kept within one degree of the set temperature.

* This feature is available only for SD-120H3 with a biomass furnace as the heat source.

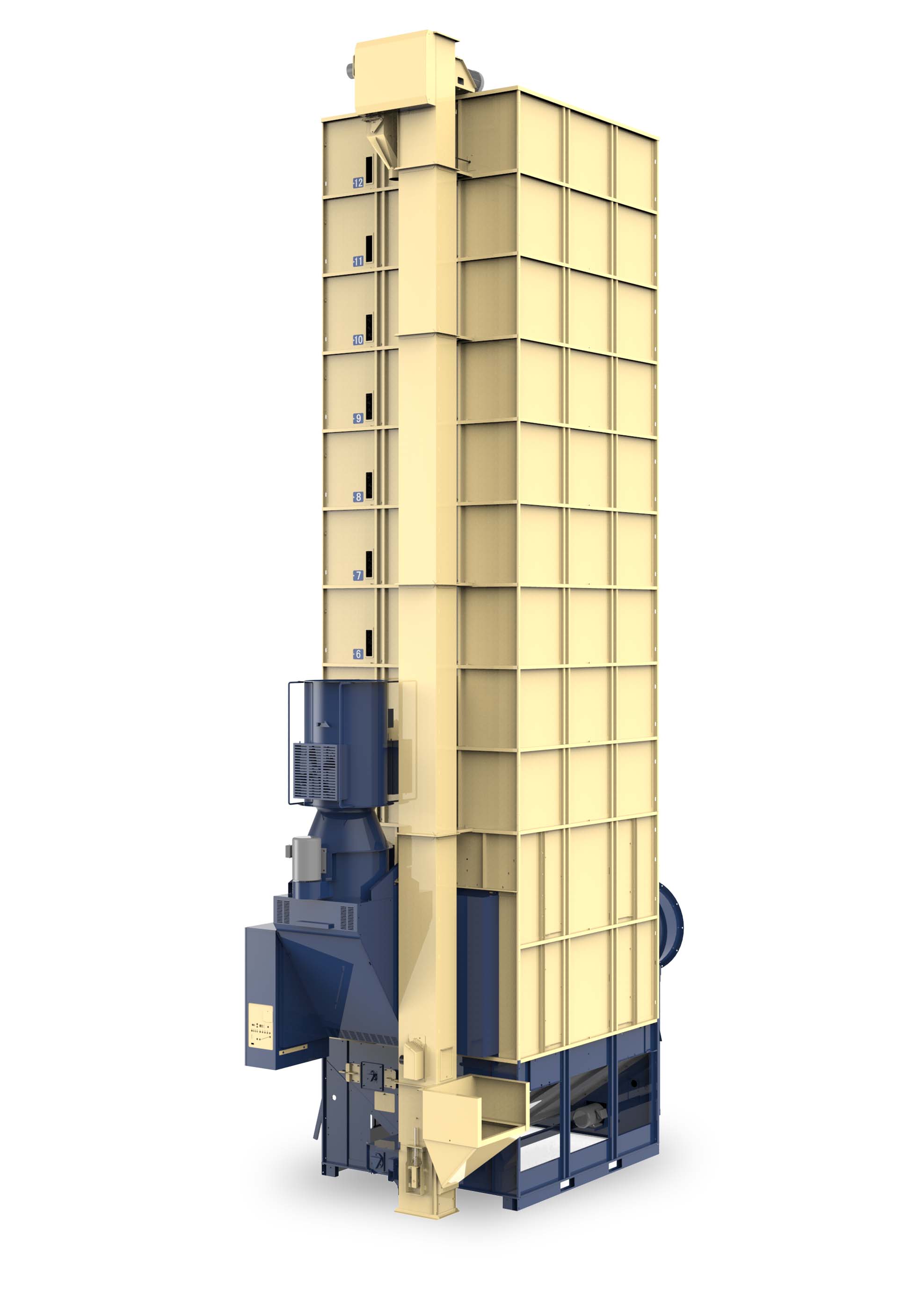

Upper Box

- The robust structure supports to withstand the weight of a fully-loaded amount.

- The main panels are made of stainless steel for durability.

Lower and Upper Screw

- A heavy-duty screw keeps the conveying stable.

- The edge of the screw has two layers of hardened steel and stainless steel.

Drying Chamber

- The grains are dried mildly, evenly, and speedily by the effectively designed 4-layer drying chamber.

- The screens are made of stainless steel for durability.

Moisture Sensors

- Our original moisture sensor has high reliability, durability, and accuracy.

- The grains’ moisture is measured every 30 minutes during the drying operation.

- When the measured grain moisture reaches the set value, drying is automatically stopped.

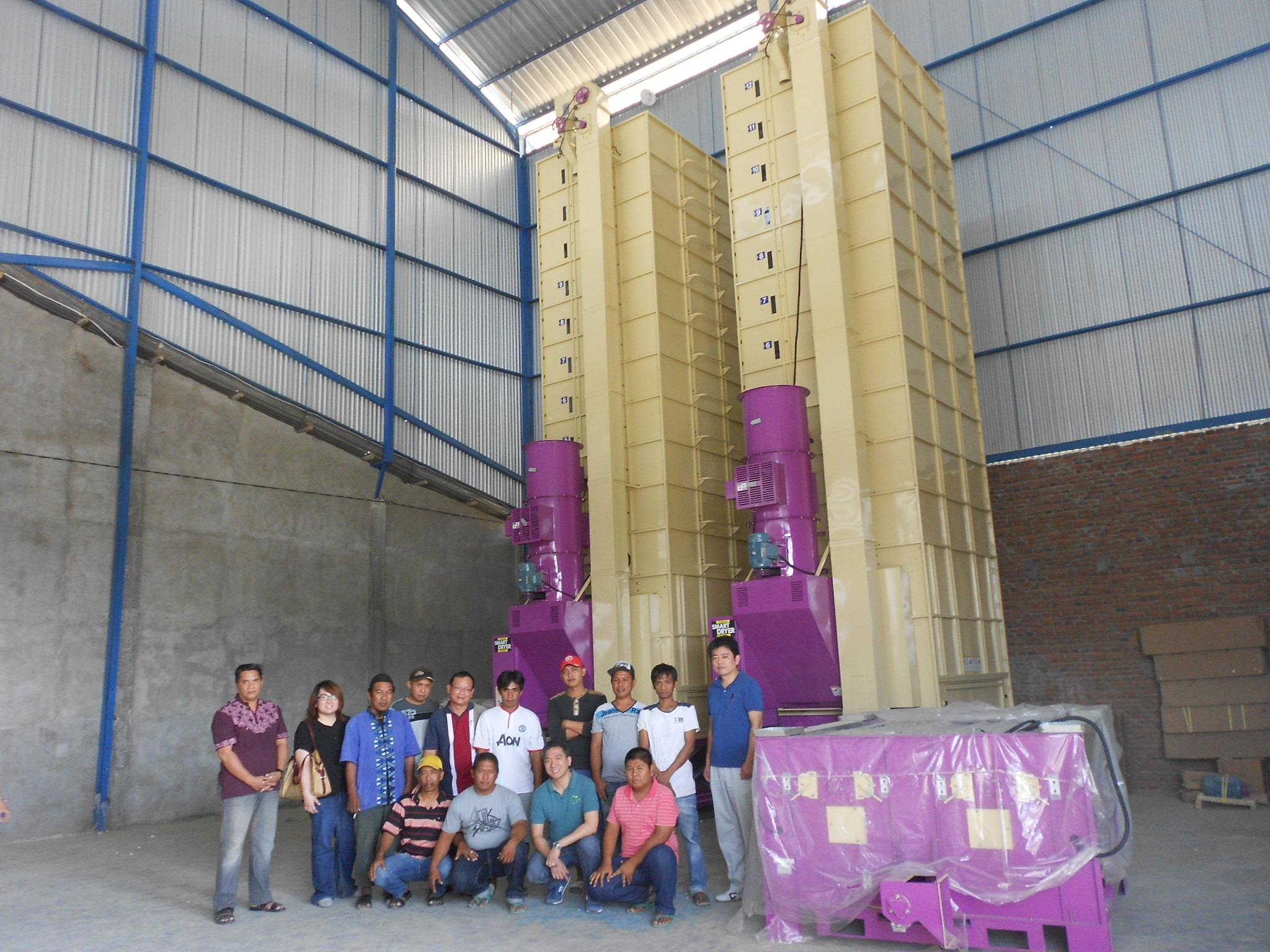

Customer Stories

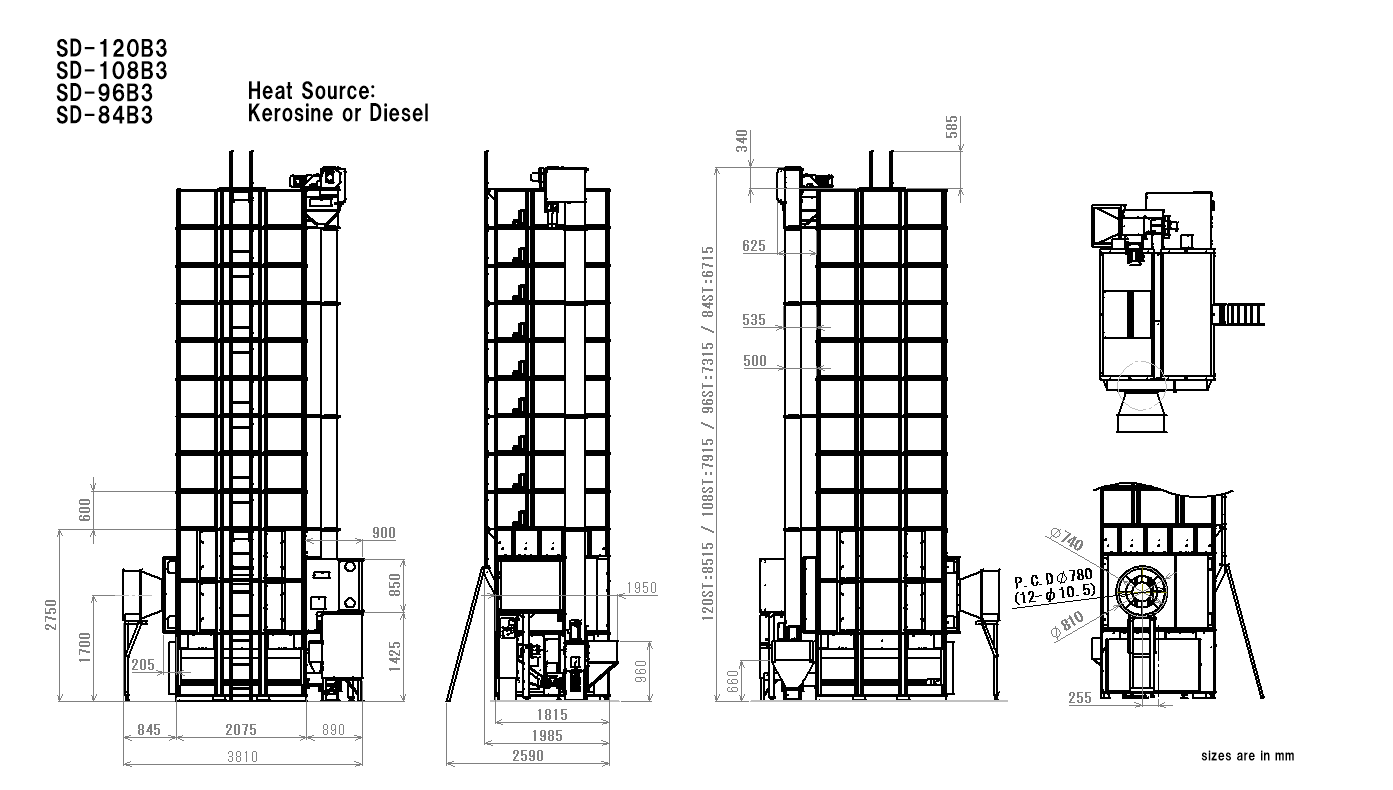

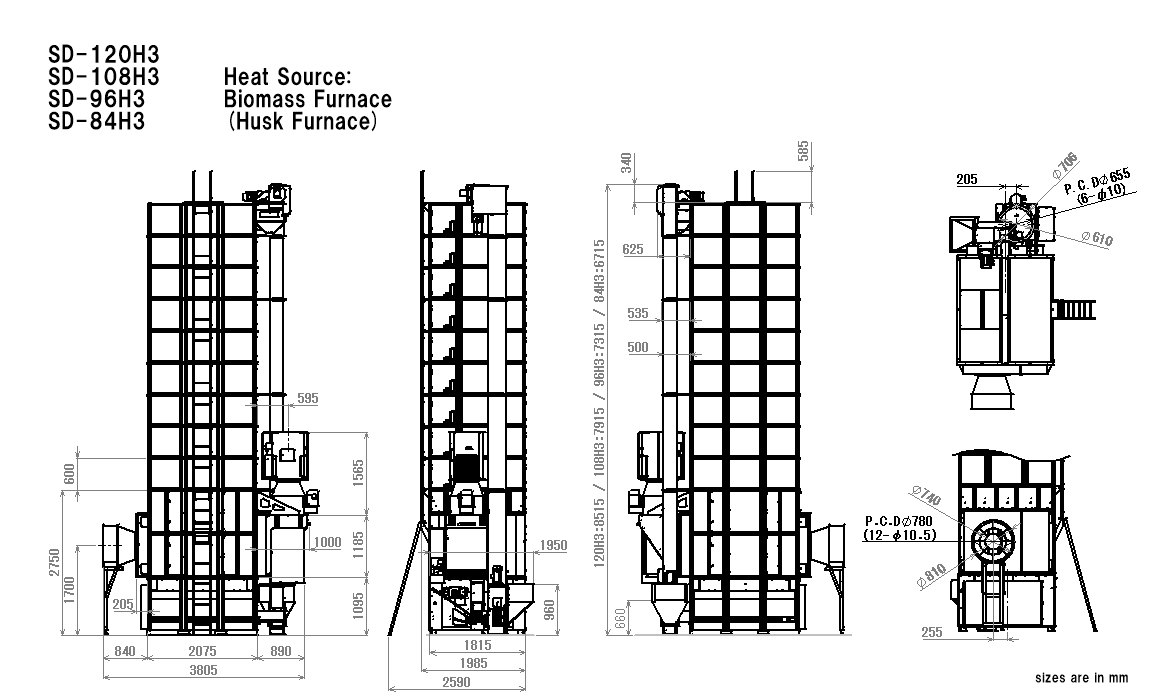

Specifications

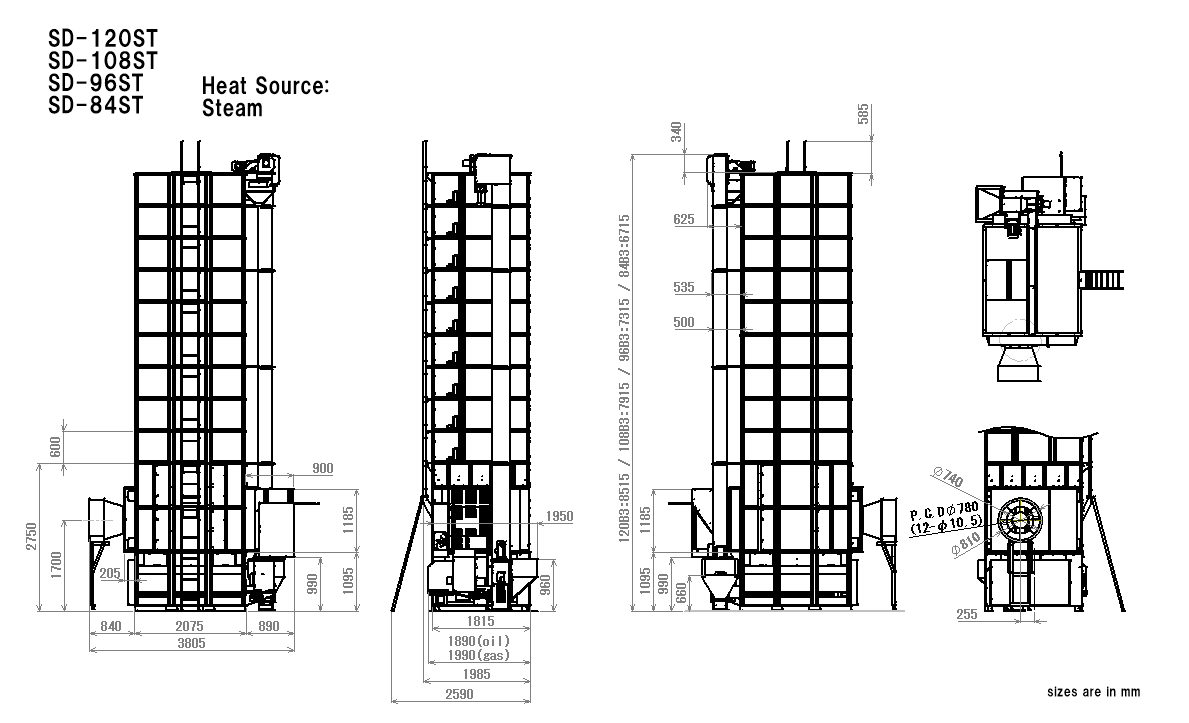

Specs for:

SD-84H3, SD-96H3, SD-108H3, SD-120H3

SD-84B3, SD-96B3, SD-108B3, SD-120B3

Specs for:

SD-84B3G, SD-96B3G, SD-108B3G, SD-120B3G

SD-84ST, SD-96ST, SD-108ST, SD-120ST

| Model Name | SD-84H3 | SD-96H3 | SD-108H3 | SD-120H3 | SD-84B3 | SD-96B3 | SD-108B3 | SD-120B3 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Heat Source | Category | - | Husk furnace | Kerosine or Diesel | ||||||

| Type | - | - | Gun type | |||||||

| Combustion amount | - | - | 9-18L/h | |||||||

| Boiler capacity | t/h | - | - | |||||||

| Boiler pressure | MPa | - | - | |||||||

| Handling Capacity (Paddy 560g/litter) |

Maximum | kg | 8,400 | 9,600 | 10,800 | 12,000 | 8,400 | 9,600 | 10,800 | 12,000 |

| Minimum | kg | 2,000 | ||||||||

| Net weight | kg | 1,920 | 1,980 | 2,040 | 2,100 | 1,920 | 1,980 | 2,040 | 2,100 | |

| Filled weight | kg | 10,320 | 11,580 | 12,840 | 14,100 | 10,320 | 11,580 | 12,840 | 14,100 | |

| Dimensions | Length | mm | 3,805 | |||||||

| Width | mm | 1,958 | ||||||||

| Height | mm | 6,715 | 7,315 | 7,915 | 8,515 | 6,715 | 7,315 | 7,915 | 8,515 | |

| Blower Type | - | Diagonal flow fan / Belt driven type | ||||||||

| Voltage | - | 3 Phase 220(440)V-60Hz , 380V-50Hz | ||||||||

| Required Power | Blower | kW | 4.0 | |||||||

| Lower screw | kW | 0.55 | ||||||||

| Bucket elevator | kW | 1.5 | ||||||||

| Dust exhauster | kW | 0.1 | ||||||||

| Operation panel | kW | 0.05 | ||||||||

| Shutter drum | kW | 0.06 | ||||||||

| Moisture sensor | kW | 0.015 | ||||||||

| Suction blower | kW | 2.2 | - | |||||||

| Damper | kW | 0.006 | - | |||||||

| Adjuster | kW | 0.006 | - | |||||||

| Burner | kW | - | 0.25 | |||||||

| Sum | kW | 8.49 | 6.53 | |||||||

| Performance | Loading speed | t/h | 10 | |||||||

| Unloading speed | t/h | 9 | ||||||||

| Loading time | min | 50 | 58 | 65 | 72 | 50 | 58 | 65 | 72 | |

| Unloading time | min | 57 | 65 | 73 | 81 | 57 | 65 | 73 | 81 | |

| Drying rate | %/h | 1.0~1.5 | 1.0~1.5 | 0.9~1.5 | 0.8~1.5 | 0.7~0.9 | ||||

| Necessary heat quantity | kcal/h | 120,000 | 120,000 | 140,000 | 150,000 | - | - | - | - | |

| kW | 140 | 150 | 160 | 170 | - | - | - | - | ||

| Model Name | SD-84B3G | SD-96B3G | SD-108B3G | SD-120B3G | SD-84ST | SD-96ST | SD-108ST | SD-120ST | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Heat Source | Category | - | LNG | Steam | ||||||

| Type | - | Gun type | - | |||||||

| Combustion amount | - | 9-18Nm3/h | - | |||||||

| Boiler capacity | t/h | - | 0.4 | |||||||

| Boiler pressure | MPa | - | 0.6 | |||||||

| Handling Capacity (Paddy 560g/litter) |

Maximum | kg | 8,400 | 9,600 | 10,800 | 12,000 | 8,400 | 9,600 | 10,800 | 12,000 |

| Minimum | kg | 2,000 | ||||||||

| Net weight | kg | 1,920 | 1,980 | 2,040 | 2,100 | 1,920 | 1,980 | 2,040 | 2,100 | |

| Filled weight | kg | 10,320 | 11,580 | 12,840 | 14,100 | 10,320 | 11,580 | 12,840 | 14,100 | |

| Dimensions | Length | mm | 3,805 | |||||||

| Width | mm | 1,958 | ||||||||

| Height | mm | 6,715 | 7,315 | 7,915 | 8,515 | 6,715 | 7,315 | 7,915 | 8,515 | |

| Blower Type | - | Diagonal flow fan / Belt driven type | ||||||||

| Voltage | - | 3 Phase 220(440)V-60Hz , 380V-50Hz | ||||||||

| Required Power | Blower | kW | 4.0 | |||||||

| Lower screw | kW | 0.55 | ||||||||

| Bucket elevator | kW | 1.5 | ||||||||

| Dust exhauster | kW | 0.1 | ||||||||

| Operation panel | kW | 0.05 | ||||||||

| Shutter drum | kW | 0.06 | ||||||||

| Moisture sensor | kW | 0.015 | ||||||||

| Suction blower | kW | - | - | |||||||

| Damper | kW | - | - | |||||||

| Adjuster | kW | - | - | |||||||

| Burner | kW | 0.25 | - | |||||||

| Sum | kW | 6.53 | 6.28 | |||||||

| Performance | Loading speed | t/h | 10 | |||||||

| Unloading speed | t/h | 9 | ||||||||

| Loading time | min | 50 | 58 | 65 | 72 | 50 | 58 | 65 | 72 | |

| Unloading time | min | 57 | 65 | 73 | 81 | 57 | 65 | 73 | 81 | |

| Drying rate | %/h | 0.7~0.9 | 1.0~1.5 | 1.0~1.5 | 0.9~1.5 | 0.8~1.5 | ||||

| Necessary heat quantity | kcal/h | - | - | - | - | 120,000 | 120,000 | 140,000 | 150,000 | |

| kW | - | - | - | - | 140 | 150 | 160 | 170 | ||

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- What types of heat sources are supported?

-

The supported heat sources are (1) combined use with a rice husk combustion furnace (newly purchased, connected to an existing combustion furnace, etc.), (2) diesel, (3) LNG/LPG gas, and (4) steam generated by a steam boiler. We will discuss with you which type of heat source is best for the country or region where it will be installed and decide on the type.

- What is the drying time?

-

It depends on the country, climate, temperature, and the type of paddy. We will work with you to calculate the appropriate drying time based on the initial and appropriate moisture content.

- How big are the machines, and how much space do they require?

-

We have various models of different sizes. Once you tell us the available space in your facility, we will suggest the appropriate model. If you are planning to build a warehouse to house your machines, we can consult and advise you on how much space will be required depending on how many units will be installed and what the heat source will be.

- What type of voltage is used?

-

The shipping specification will vary depending on the three-phase voltage used in your region. Please contact us to confirm.

- What materials are used, and how durable are they?

-

Each part of our equipment has been designed for maximum durability. If you would like to know about specific parts, please contact us, and we will gladly give you full details and specifications.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.

View

View