Dry Polisher KAPIKA DP-3001

A dry method is used to remove bran that standard rice milling processes miss. Since no water is used, initial setup and ongoing running costs are lowered.

Maintenance & Troubleshooting:

Product Features

Less residual bran on the surface of milled rice:

- Retains flavor longer

- Better appearance

- Easier to cook

- Less water pollution

- No water piping is required

High Milling Recovery Rate, Easy Operation

- Durability: Consumable parts last approximately as long as those used in our vertical polisher.

- Running Costs: Since it does not use water, initial and running costs are significantly reduced.

- Usability: The operation is straightforward, just like a standard polisher.

- Quality: The occurrence of broken rice during dry polishing is far lower than standard polishing methods.

- Productivity: Overall, our customers report higher milled rice recovery rates.

Time-Savings & Cost Reduction

Compared to our previous model, the DP-3001 requires far less time for maintenance than its predecessors. Its open structure design allows easy cleaning of the bran inside the machine in under 10 minutes. Replacing resistance parts can be done in around 50 minutes (6 hours for DP-3000).

Cleaner & Shinier Rice

- Without water or other materials, 0.8% of residual bran (ration by weight) is successfully removed.

- By setting the length longer than the roll’s diameter, retention time is prolonged, thereby removing bran via the processing screen.

- Residual bran is effectively released via suction and an exhaust fan.

- The gap between screen and roll is narrow, approximately equivalent to two rice grains, enabling a higher degree of polishing.

Physical Properties

| Ordinary Milled Rice | KAPIKA Rice | ||

|---|---|---|---|

| Whiteness Degree | % | 38.0 – 41.0 | 40.0 – 43.0 |

| Turbidity | ppm | 50 - 60 | less than 40 |

| Cubic Weight | 11 | 830 – 840 | 850 – 870 |

| Fat Acidity | mgkoh/100 | 3.8 | 2.8 |

| Taste Value | score | 75 | 78 |

* Whiteness: Measured by the C-300 rice quality measurement instrument by Kett.

* Turbidity: Measured using the recommended method of the Japan Rice Millers Association.

* Variability: Results will vary depending on the variety and condition of brown rice and the milling process.

Rinsed Rice Water

| Ordinary Milled Rice | KAPIKA Rice | ||

|---|---|---|---|

| BOD | mg/l | 1,970 | 1,030 |

| COD | mg/l | 1,030 | 540 |

| SS | mg/l | 1,120 | 473 |

| Total Nitrogen | mg/l | 53 | 25 |

| Total Phosphide | mg/l | 47 | 24 |

| Fat | g/100g | 0.2 | 0.1 |

| Starch | g/100g | 0.04 | 0.01 |

Data was sourced from the Japan Food Research Laboratories.

* Water quality was analyzed using the water after the rice was washed.

For each type of rice, 1.5kg of rice was washed three times using a total of 3.5 liters of water.

Customer Stories

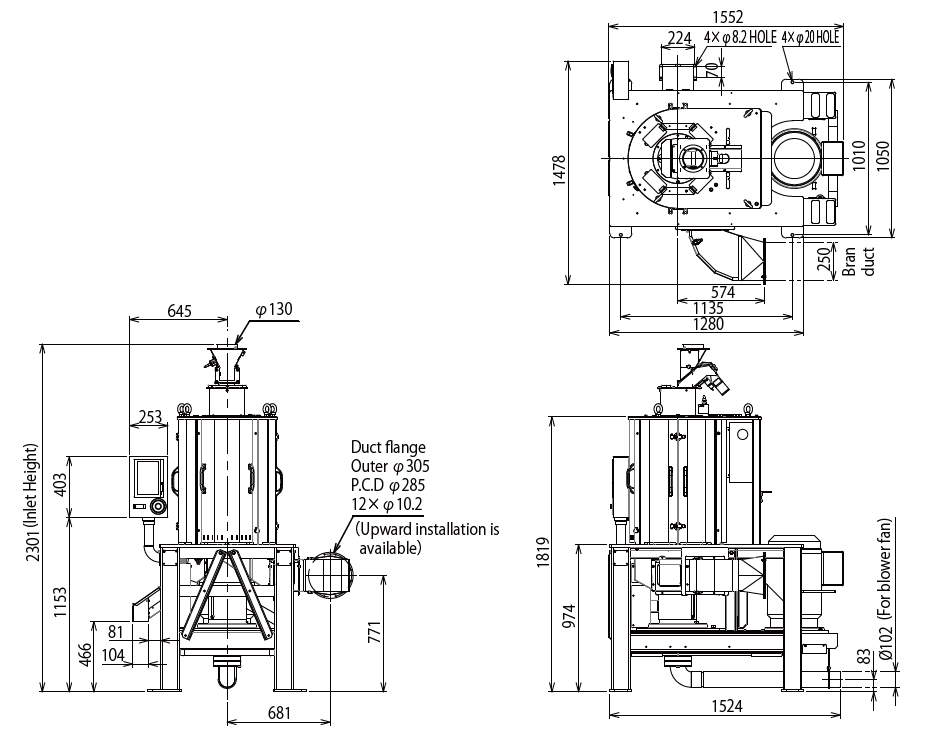

Specifications

| Model Name | DP-3001 | ||

|---|---|---|---|

| Demensions | Length | mm | 1,552 |

| Width | mm | 1,478 | |

| Height | mm | 2,301 | |

| Net weight | kg | 1,401 | |

| InputCapacity on Short, Medium Grain Rice | kg/h | 3,000 ~ 5,000 | |

| Power | - | 3-phase 200 / 220 / 380 / 420 / 460V |

|

| Required Power | Main Machine | kw | 30 |

| Blowing Fan | kw | 2.2 | |

| Sum | kw | 32.2 (200V) | |

| Remarks | - | Suction Blower is optional | |

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- Can the white rice discharge of this machine be placed on the left side?

-

Yes. In fact, our DP-3001 provides four combinations for the white rice and bran discharge locations. We offer free consulting — please feel free to contact us to discuss your requirements.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.