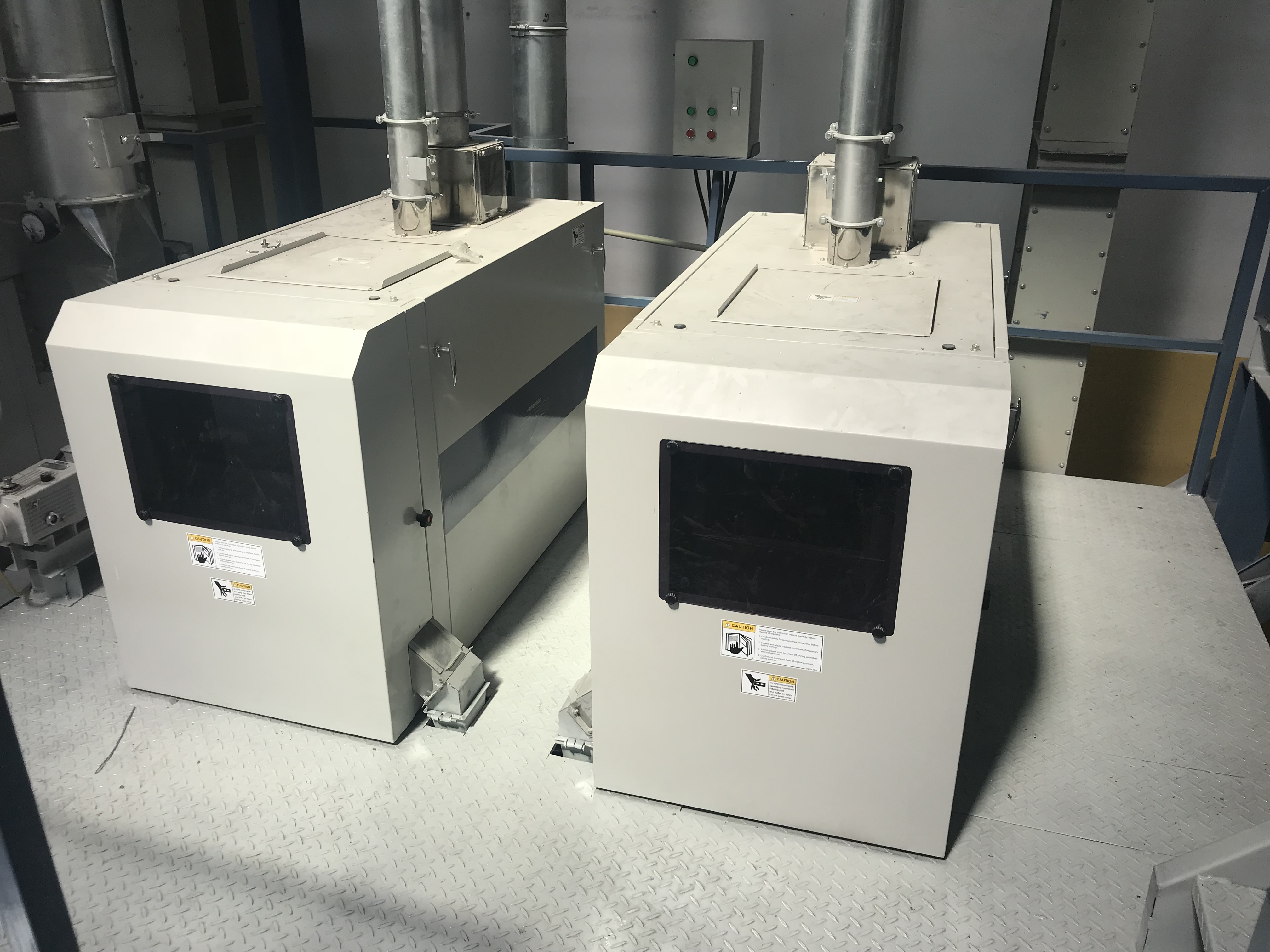

Grading Sifter SF-301

Features highly efficient and accurate separation technology. Basic maintenance can be performed without tools, making daily operation easy.

Maintenance & Troubleshooting:

Product Features

Two-Way Sorting Motion

Three sieves placed from top to bottom move rotationally and linearly, enabling a higher separating rate. Three sieves effectively separate fine grains, broken grains, and bran balls from milled rice. They move in a combined circular motion, which minimizes vibration.

Compact Design

Because of the two-way motion of the smaller sieves, these machines can process the same capacity as traditional rotary shifters. As a result, our machines are much more compact than standards.

Adjustable Outlet Direction

The operator can select to output the grain to the left or right.

Easy to Maintain

Detachable fixing knobs allow manual cleaning of internal parts and sieve replacement without any tools.

Customer Stories

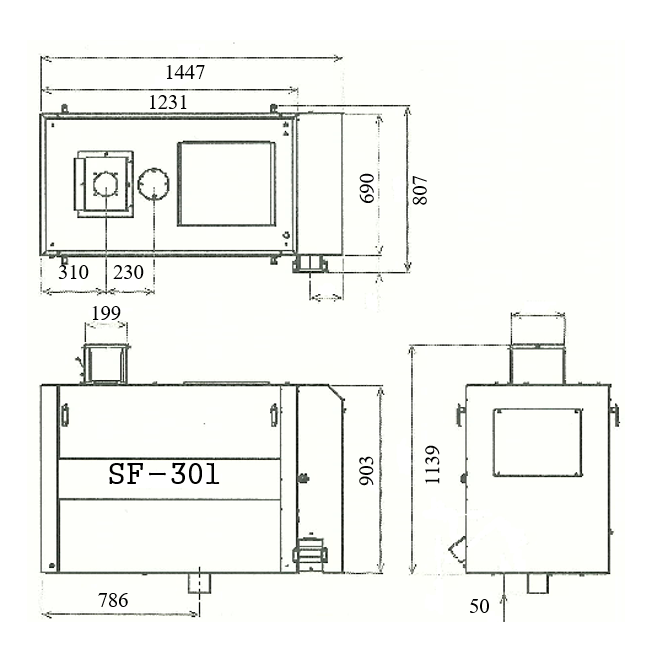

Specifications

| Model Name | SF-301 | ||

|---|---|---|---|

| Length | mm | 1,447 | |

| Width | mm | 807 | |

| Height | mm | 1,139 | |

| Weight | kg | 176 | |

| Capacity | t/h | 3 (Max) | |

| Voltage | mm | 3-phase 200V | |

| Power | - | 3-phase 200 / 220 / 380 / 420 / 460V |

|

| Req.Power | kW | 0.4 | |

| Mesh of each sieve | 1st sieve | mm | 4.38 |

| 2nd sieve | mm | 1.94 | |

| 3rd sieve | mm | 1.04 | |

* Due to Yamamoto’s continuous development program, specifications and dimensions may change.

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.