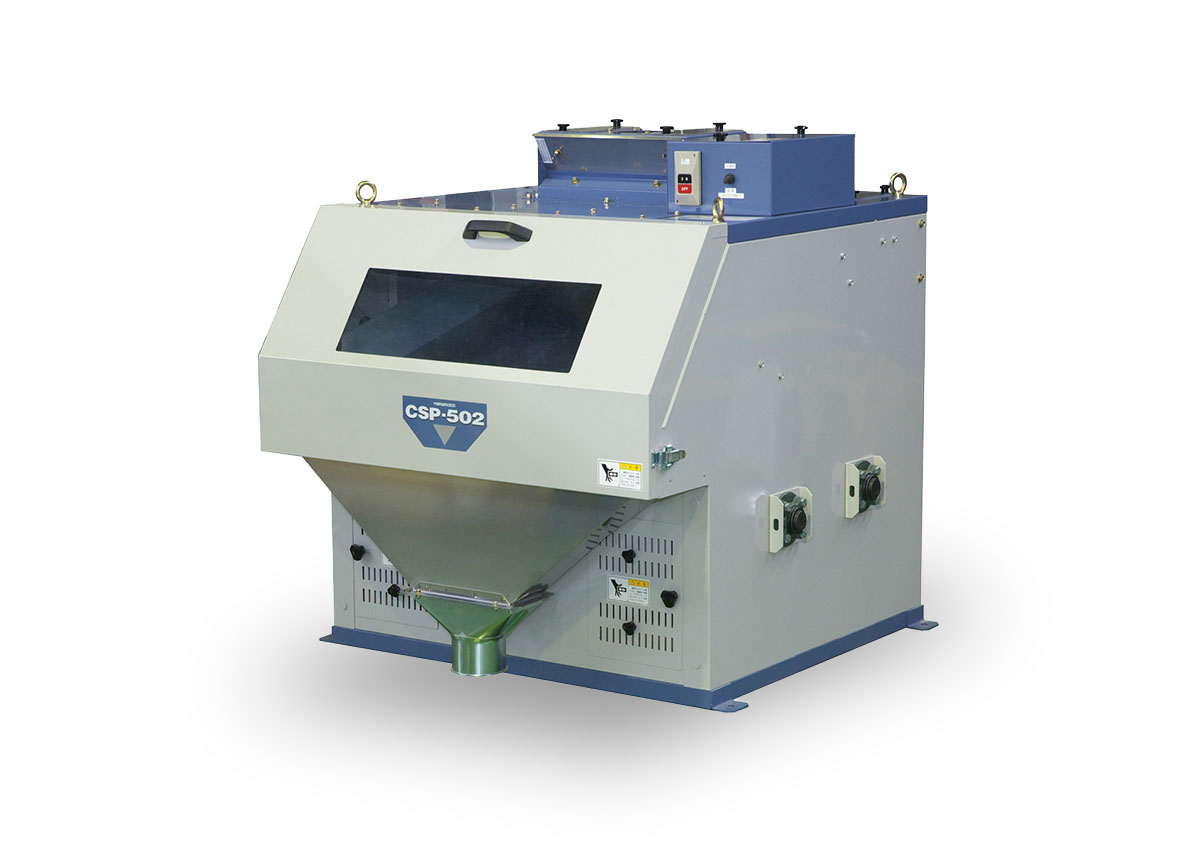

De-Stoner CSP-502

Closed circuit type

Primary and secondary sorting decks work to minimize the amount of brown rice in the discharged stones, thereby maximizing the milling recovery rate.

The discharge process takes only three minutes.

Maintenance & Troubleshooting:

Product Features

Secondary Screen Mechanism

Our secondary screen mechanism drastically reduces the amount of brown rice discharged with stones and results in the high milling recovery rate.

Automatic Discharge System

The automatic discharge system is designed to minimize the need for manual operation and can be adjusted in only three minutes.

Wide Cleaning Door

The machine's front and back feature a wide door for easy cleaning. The screen is also easily accessed for thorough cleaning.

Adjusting Screen Angle

The screen angle can be adjusted optimally to suit the flow amount and characteristics of the material being processed.

Customer Stories

Specifications

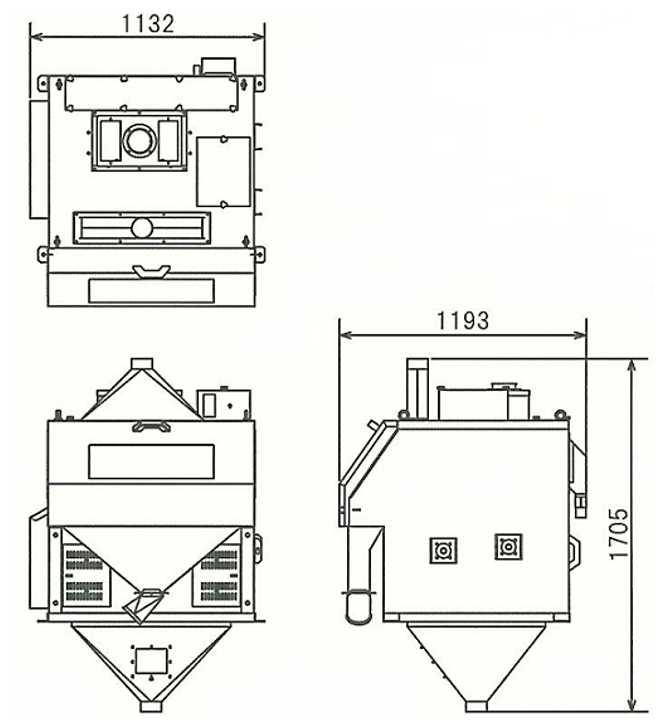

| Model Name | CSP-502 | ||

|---|---|---|---|

| Demensions (Standard specific) |

Length (mm) | mm | 1,193 |

| Width | mm | 1,132 | |

| Height | mm | 1,705 | |

| Net Weight | kg | 255 | |

| Capacity | t/h | 5 (Max) | |

| Power | - | 3-phase 200 / 220 / 380 / 420 / 460V |

|

| Motor | kW | 1.5 | |

* We are continuously innovating. Therefore specifications and dimensions are subject to change.

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- Is it possible to change the timing and duration of de-stoning?

-

Yes. It is possible by using a timer, even while sorting, according to the percentage of stones in the material.

- Can the De-stoner process grains other than paddy or brown rice?

-

Yes. Our De-stoner can sort various other grains. We offer free consulting. Please feel free to contact us with details of the grains and seeds you wish to sort. We will confirm whether our de-stoner can handle them.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.