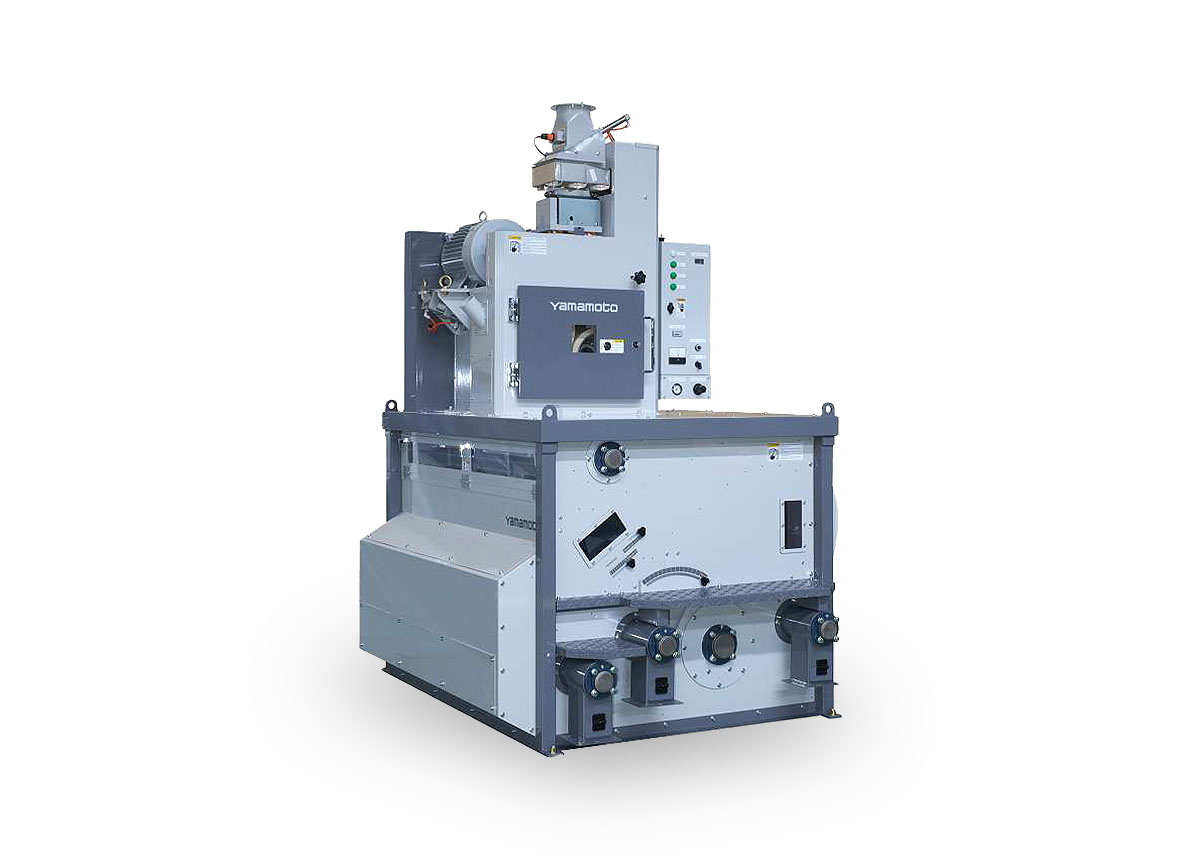

Paddy Husker YSA-100

Closed circuit type

High-Performance Paddy Husker.

Easy to operate. Superior separation accuracy.

Maintenance & Troubleshooting:

Product Features

High Husking Performance

The husking performance is improved with inclining rubber rolls, a pneumatic husking structure, and an adjustable chute angle.

Steady Operation

No adjustment is necessary once the aspiration is appropriately set because the amount of input paddy is kept constant by the vibratory feeder and sensor. The aspirator has inspection windows on three sides, allowing the operation to be monitored and providing easy maintenance access to interior parts.

Easy Maintenance

Our Paddy Husker is designed for easy maintenance and cleaning during use. Features a cover that can be opened without the need for tools.

Customer Stories

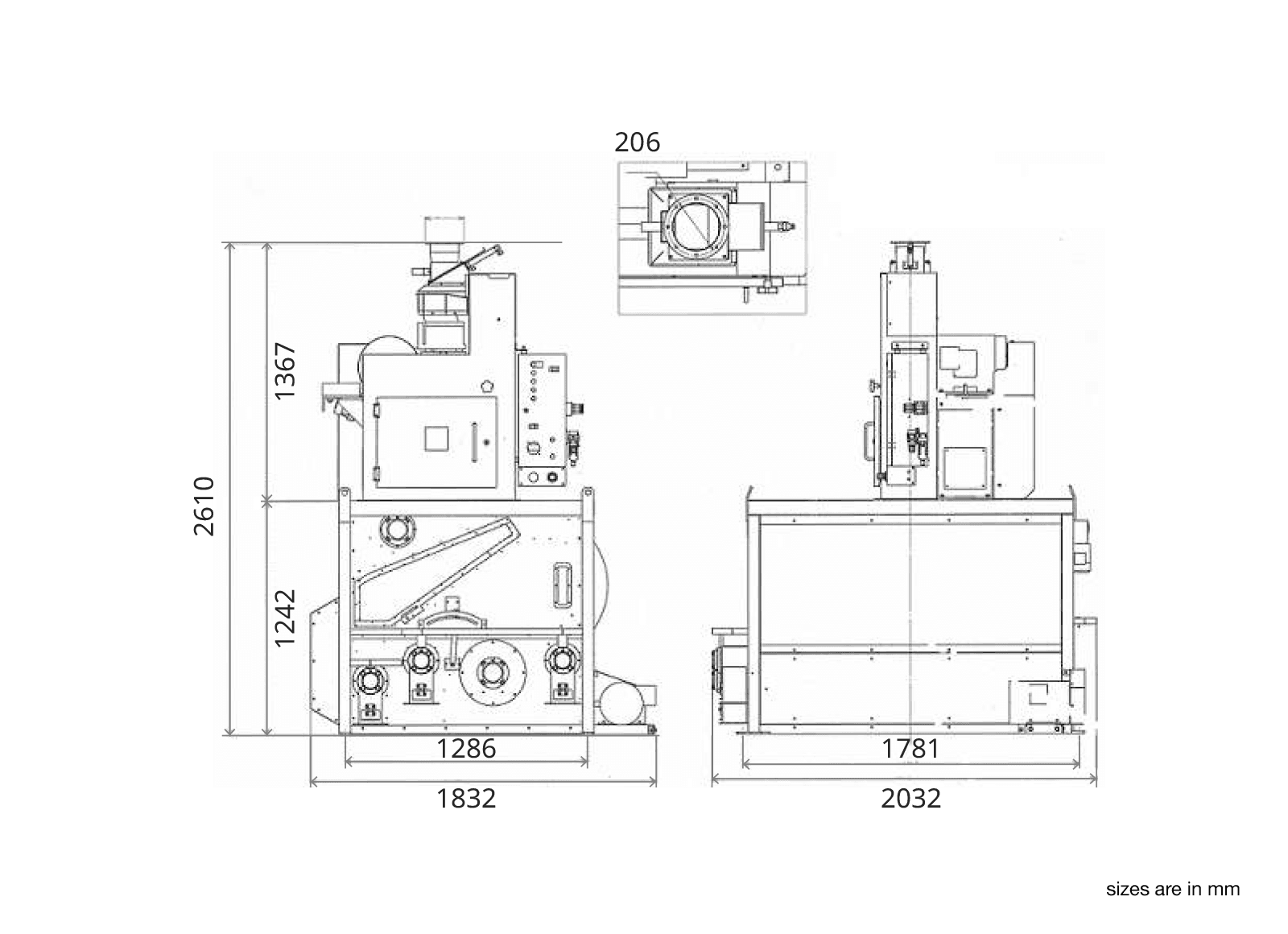

Specifications

| Model Name | YSA-100 | ||

|---|---|---|---|

| Length | mm | 2,052 | |

| Width | mm | 1,860 | |

| Height | mm | 2,600 | |

| Rubber Roll | inch | 10 | |

| Input Capacity (long grain-short grain) |

t/h | 3~7.5 | |

| Net Weight | kg | 1,300 | |

| Power | - | 3-phase 220 / 380 / 420V |

|

| Motor | Head (SH-100) | kW | 7.5 |

| Aspirator (AS-100) | kW | 3.9 | |

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- What is the machine’s capacity?

-

It depends on the type and size of the paddy to be processed. So please let us know the information about the paddy.

- What voltage is required?

-

Please let us know the voltage available at your facilities, and we can adjust the motor to match the supply available.

- Besides electricity, what else does the machine require to operate?

-

Our Paddy Husker requires a 0.65MPa air compressor to operate.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.