52. Parboiling 4

- INDEX -

Hardening characteristics of rice grain

Discoloring characteristics

Milling Method for Parboiled Rice

Properties at Husking

Properties at Rice Polishing

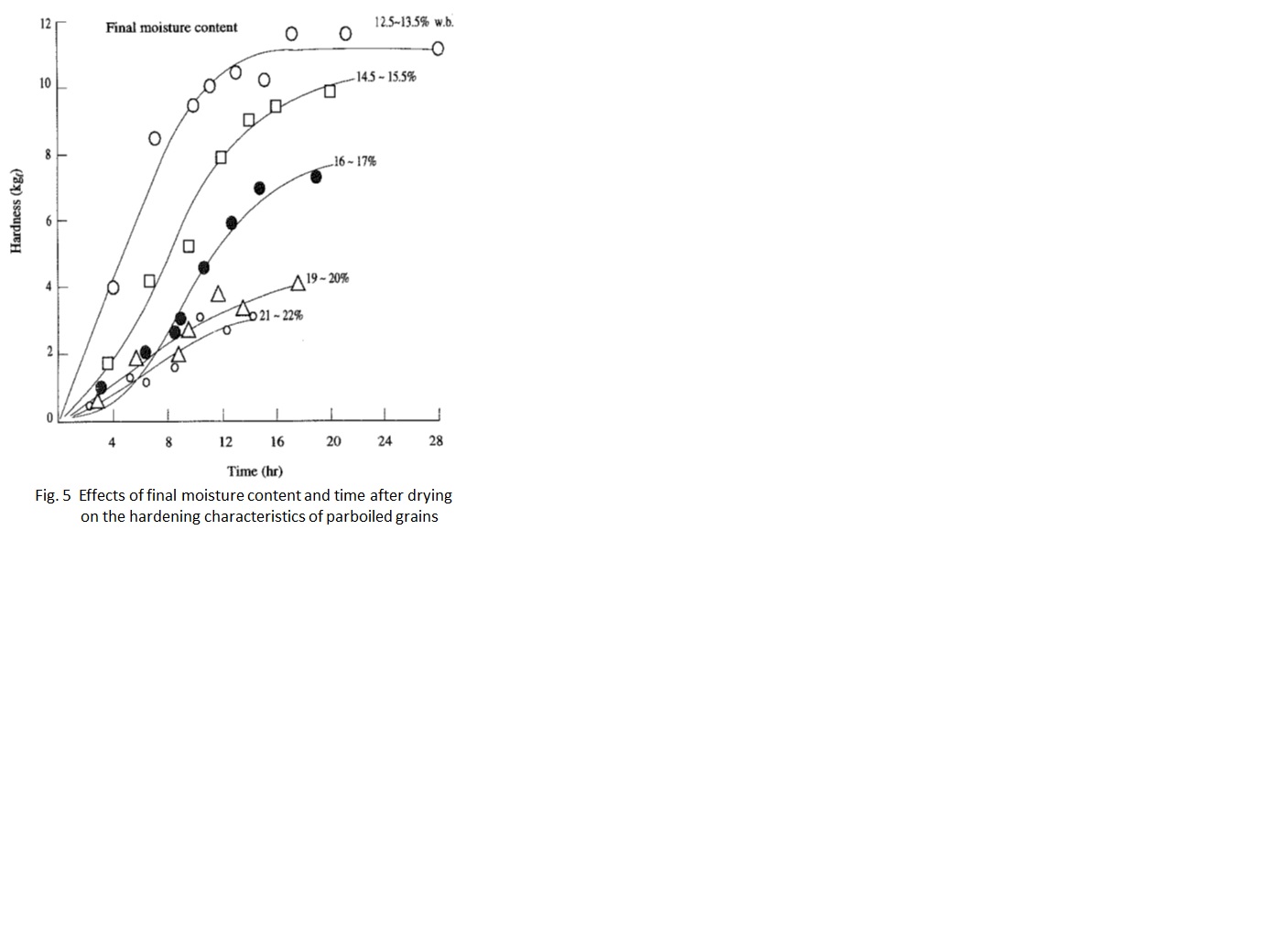

Hardening characteristics of rice grain

A large factor that accelerates hardening is gelatinization of starch. During the drying process after parboiling, a high moisture content is maintained for a while. Then, the starch degrades, namely, is reconstructed. A sufficient supply of water for the soaking process and steaming at a higher temperature for a longer time result in harder products.

Retrogradation is said to stop at a moisture content of about 15% w.b. The time and the temperature until the above condition is achieved influence the degree of retrogradation. As described previously, the moisture content during the drying period remains in the range accompanying retrogradation. Therefore, the degree of gelatinization of products is determined by the final moisture content and the time required to achieve the final moisture content.

It then determines the hardness of rice grains.

Figure 5 shows the relationship between drying rate and moisture content. When the products are dried to 16% w.b. or less, hardness increases gradually for the first several hours and then rapidly. When the drying process stops at about 20% w.b., the starch is subjected to retrogradation and hardness shows a slow rate of increase, resulting in not so much hardening after being left even for a long time.