79. Causes of Losses and Magnitude of Losses 2

- INDEX -

Losses in Storage

Cause

Magnitude of Losses

Losses in Transport

Cause

Magnitude of Losses

Method of Calculating Losses

Simple Sum

Cumulative Sum

Losses in Storage

Cause

The major causes of losses during storage of rice are water, heat, bacteria and mold, birds, insects, and rats.

A secondary cause is poor storage facilities which cannot protect stored rice from these major causes. An extreme case is paddy heaped on the ground in the open in rice mills in Pakistan. Major causes depend on the country, however, it is common in every country to store paddy in farmhouses, which often invite losses. The reason is that the traditional method of storage in farms is considerably unsatisfactory compared to the modern method used by warehouses along distribution channels.

Magnitude of Losses

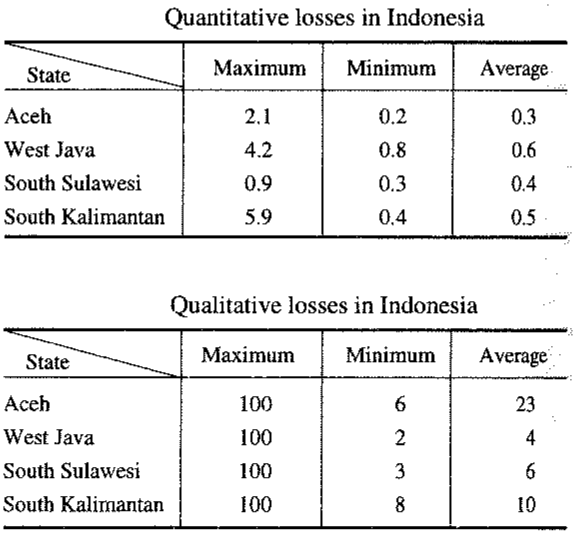

Quantitative losses:

Quantitative losses during the long-term storage test carried out in Indonesia for six months is unexpectedly low as indicated below. This is because the target warehouses were of DOLOG and KUD, which were better than those of private mills or middlemen. Therefore, the losses can be considered not to be average but the minimum. On the other hand, losses in farms are estimated to exceed 3%. Prior to commencement of this test, fumigation with methylbromide was carried out. Piling, ventilation, and care of rice during this test were done in the conventional way. A survey of losses according to cause, such as damage done by insects or by rodents could not be done.

Storage losses in farms in Indonesia:

Despite such a small number of target farms storing rice for this survey as only 24 at the beginning, it decreased to 15 at the end while their rice was sold out or eaten. Besides, in spite of the preferable stores of selected farmers to those on average, a 1.8% quantitative loss was found.

Qualitative losses:

The results of the survey carried out in Indonesia are listed in the table. Here, the defects are colored, damaged, and broken kernels. The maximum 100% losses took place in rice stored by farmers which was spoiled by rain.

Example of qualitative losses in Pakistan:

Due to the limited time afforded for the survey, periodical samplings and tests could not carried out in Pakistan. According to a survey carried out by PASSCO, losses during six months storage were 3.1$% in Sind State and 1.6% in Punjab State.

Example in Thailand:

There is a report that losses during six months storage in a 10 ton warehouse were 0.2 ? 0.3%.

Example in India:

There is a report that 6.58% corresponding to 70% of total postharvest losses which amounted to 9.33% occurred during storage.