Grading Sifter SF-31

It uses a woven screen to separate head rice, broken grains, and bran balls by size.

Note that this machine was designed specifically for short and medium grains — it is not suitable for processing long grains.

Maintenance & Troubleshooting:

Product Features

High Precision Sifting for Head Rice

Our grading sifters refine milled rice using the complex horizontal oscillation of an inclined screen combined with a circular motion. The screen angle is adjustable between 5–8 degrees.

* Screen A

Easy Operation

The sifting balls prevent the screen from jamming. The flow amount can be adjusted using an easy-to-access shutter lever.

Screen Slot Size Options

Select from 1.7, 1.8, 1.9, 2.1, or 2.2 mm.

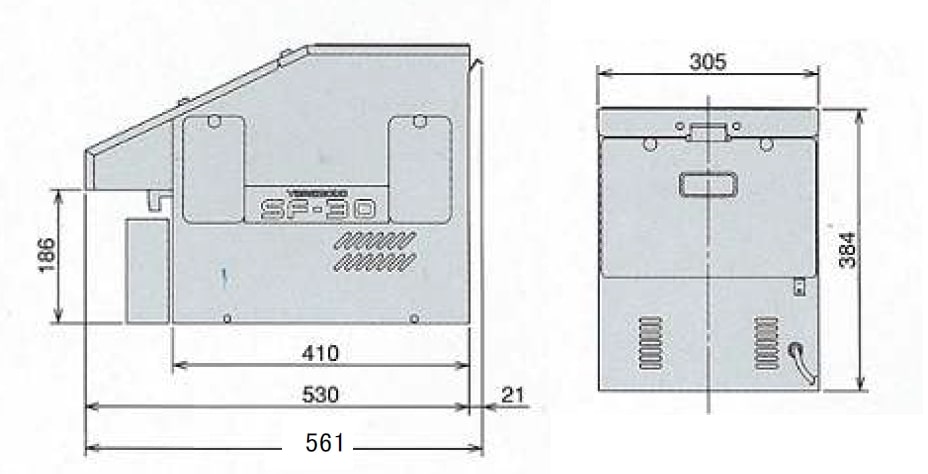

Specifications

| Model Name | SF-31 | |

|---|---|---|

| Length | mm | 561 |

| Width | mm | 305 |

| Height | mm | 384 |

| Net Weight | kg | 24 |

| Capacity | kg/h | 130 - 320 |

| Power Supply | - | 1 phase 100V |

| 100V | ||

| Standard Screen A | mm | 2.0 |

| Option Screen | mm | (Option of Screen A) 1.7 / 1.8 / 1.9 / 2.1 / 2.2 |

* We are continuously innovating. Therefore specifications and dimensions are subject to change.

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our Laboratory Equipment.

- What kind of power supply can be used for this Grading Sifter?

-

Only single-phase 100V is available. If single-phase 100V is not available in your area, please use a down transformer to make single-phase 100V and supply it to the machine. The required capacity is 1kVA or more.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.