NEW MODELUnit Type Whitener NX Series

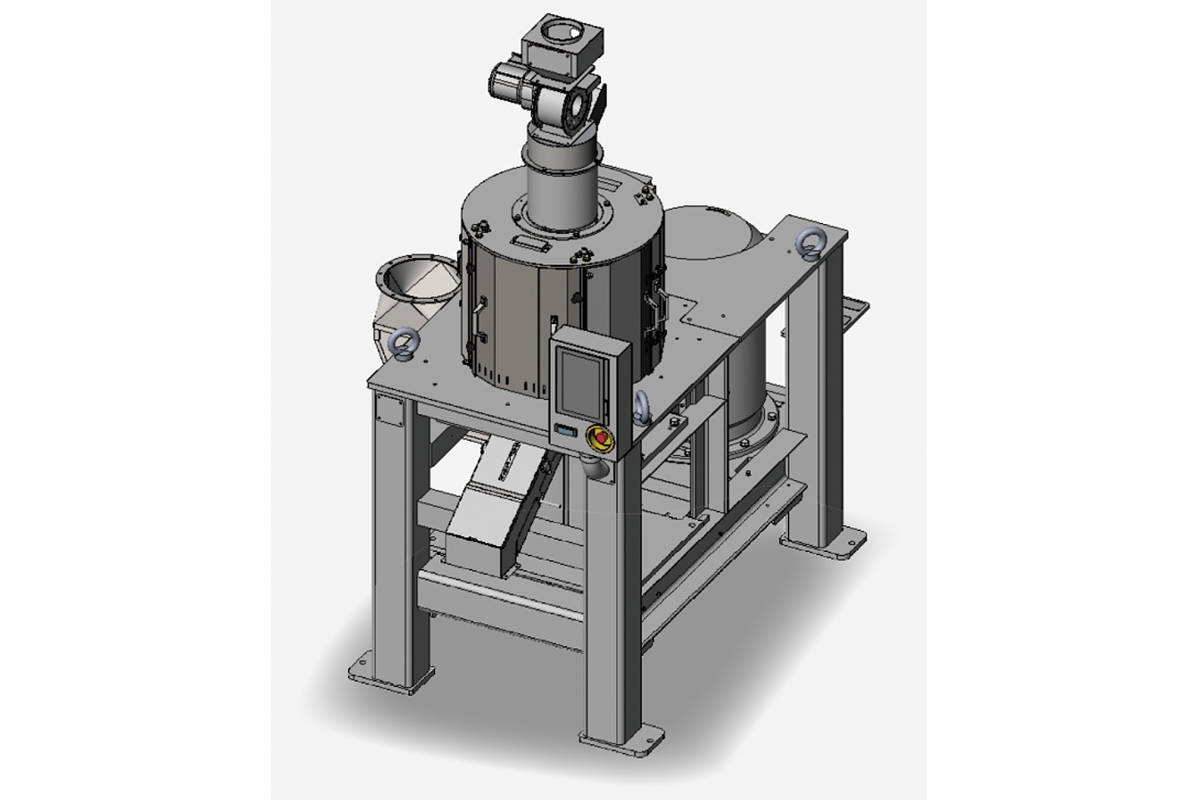

Introducing our cutting-edge vertical rice milling machine, designed to tackle workforce shortage in the industry.

With a capacity of 5,000 kg/h, this high-performance machine ensures easy operation and maintenance, reducing the operator's workload and saving labor at rice mills.

Maintenance & Troubleshooting:

Product Features

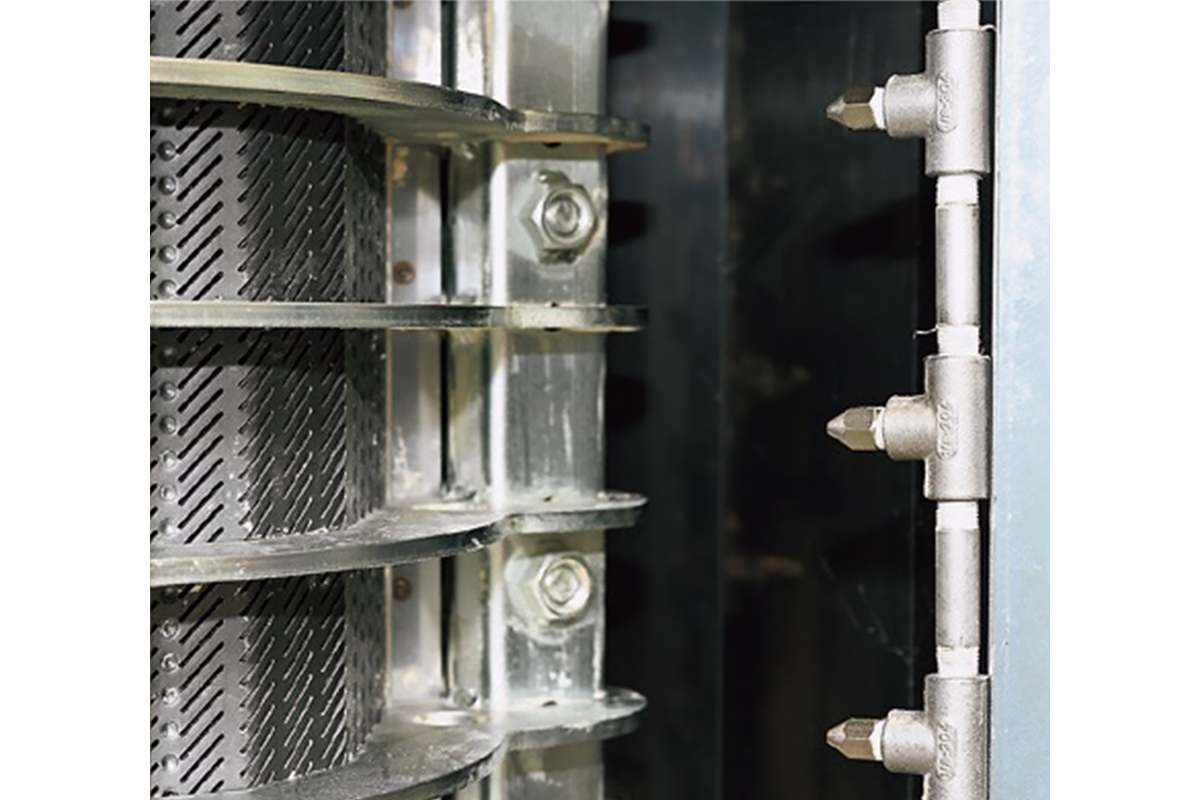

Significantly Reduces Daily Cleaning Time with New Automatic Air Blow Function

- The innovative automatic air blow function efficiently eliminates bran buildup from the screen holder, allowing for quicker and more effective daily cleaning within the machine.

Minimized Cover Design Reduces Bran Buildup and Insect Infestation

- The unit's cover has been significantly reduced for more convenient maintenance.

- The minimal cover design decreases bran buildup and insect infestation while lessening maintenance labor requirements.

Newly Designed Abrasive Section (NX-5000) Ensures Easy Replacement and Cleaning

- Using lightweight components alleviates the operator's workload during replacement and cleaning processes.

- The newly designed grinding section and enhanced bran ejection prevent uneven grinding, ultimately high-quality and high-millig-recovery-rate results.

Effortless Operation for Inexperienced Users with Comprehensive Support Functions

- The touch panel offers many support functions, allowing even inexperienced operators to feel at ease.

- Essential factory information, such as rice milling data and maintenance methods, can be recorded with just one touch, streamlining labor requirements.

- The usage time of consumable parts is easily visible, simplifying parts management and reducing operator training time. Managers can also save time by avoiding complex manuals.

- A 10.4-inch touch panel with exceptional visibility is employed for ease of use.

Space-Saving Integrated Whitening and Polishing System for Labor-Efficient Rice Mills

- The tandem configurations of abrasive and friction machines require ample installation space. However, this space-saving integrated machine enables high-quality, high-milling-recovery-rate polishing even within a small space.

- In contrast to tandem configurations, which require each machine to be started, stopped, and adjusted individually, the integrated unit can be operated using a single switch, contributing to labor savings at the facility.

Optimized Milling Recovery Rate, Rice Quality, and Milling Efficiency for Short-Grain Rice (Japonica)

- The NX Series is designed explicitly for short-grain rice, ensuring high milling recovery rate through careful milling by whitening and polishing. The integrated design allows for milling at lower temperatures, preserving the natural flavor of the rice.

- With a 5% higher effectiveness over the previous model, the control grinding part exhausts residual rice by air and the turning force of the grinding stone.

High Durability for Long-Term Use

- Automatic air blow and enhancements to various parts of the unit prevent bran buildup and insect infestation, minimizing breakdowns and ensuring years of reliable use.

Quiet Operation for a Comfortable Working Environment

- Incorporating soundproofing into the friction section of the machine's bran removal case ensures quiet operation during milling. This results in a more comfortable working environment and reduced stress for the operator.

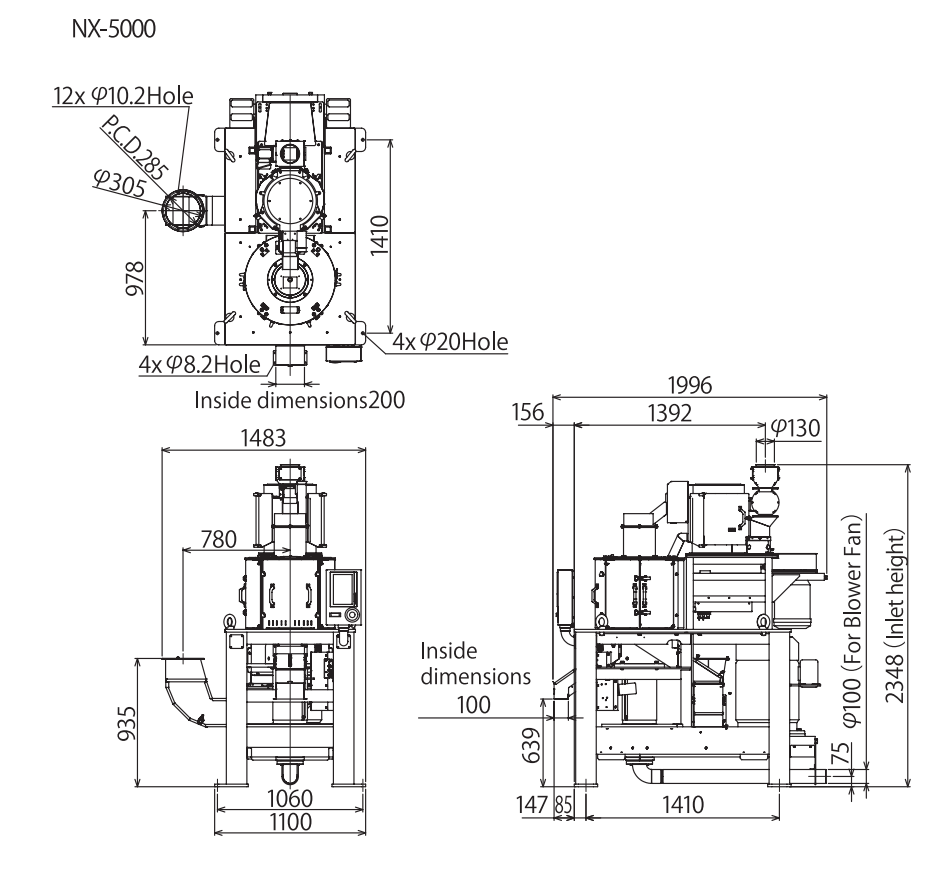

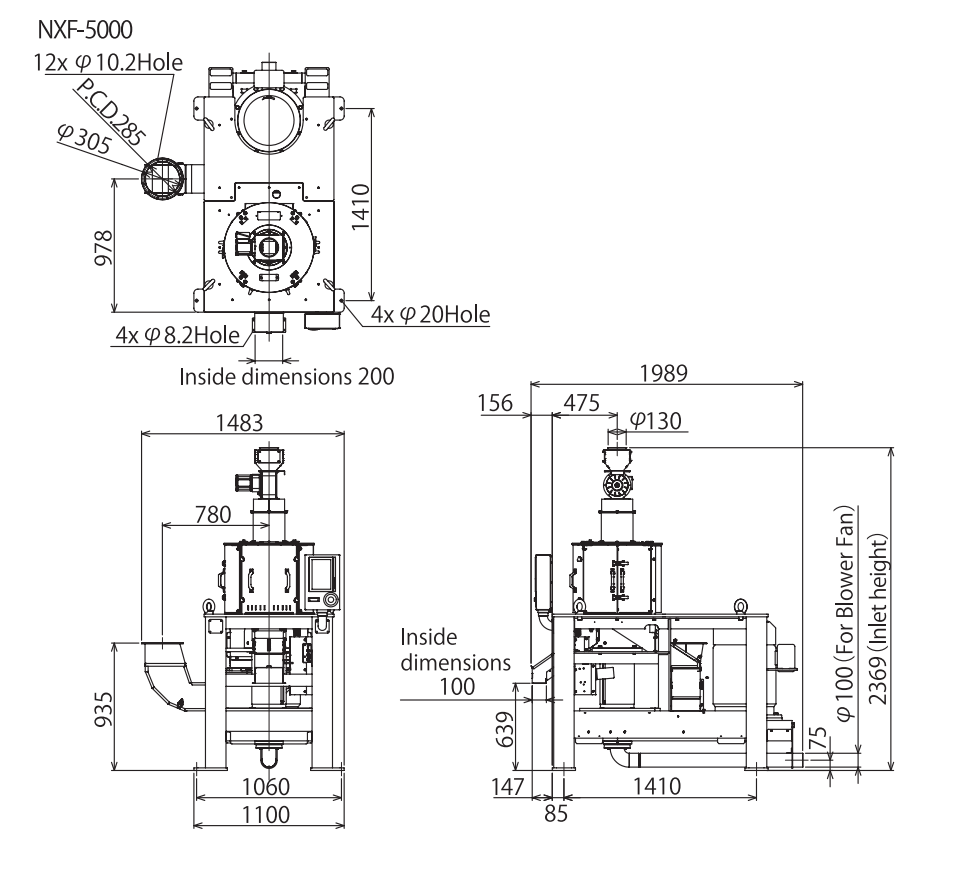

Specifications

| Model Name | Whitener + Polisher | Polisher | ||

|---|---|---|---|---|

| NX-5000 | NXF-5000 | |||

| Demensions | Length | mm | 1,996 | 1,989 |

| Width | mm | 1,483 | 1,483 | |

| Height | mm | 2,348 | 2,369 | |

| Net weight | kg | 2,110 | 1,740 | |

| Max Input Capacity for Short Grain | kg/h | 5,000 | ||

| Power Pupply | V | 3-phase 200/380/400/440/460 | ||

| Necessary Power | Abrasive Section | kW | 7.5 (10PS) | - |

| Friction Section | kW | 55 (75PS) | ||

| Blowoff Fan | kW | 2.2 | ||

| Total | kW | 64.7 (85PS) | 57.2 (75PS) | |

| Option | Unpolished Rice Processing System | |||

Please note the following:

* Power supply and wiring equipment must have a rating of 400A or higher.

* The power panel comes equipped with an inverter. In some cases, the earth leakage breaker may be triggered even when the machine is functioning correctly, depending on the specific type of breaker utilized.

* To avoid potential issues, we recommend consulting with a qualified electrician to ensure the use of an earth leakage breaker with a sensitivity current of 200 mA or higher and an operating time of 0.1 seconds or greater. Alternatively, a breaker designed to prevent harmonic interference may also be suitable.

* The main specifications, including contents, illustrations, appearance, colors, and markings, are subject to change without prior notice as part of our ongoing commitment to product improvement.

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- How do we know which model will best fit our processing capacity requirements?

-

Please get in touch with us with details of your planned processing capacity. We will recommend machines and milling processes to match your needs.

- Can this machine process both short and long-grain?

-

This model is specifically designed for processing short-grain. It is not suitable for processing long grain. Please get in touch with us with details of your requirements, and we will recommend a suitable machine from our lineup.

For Owners

Maintenance & Troubleshooting:Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.