Grain Dryers and Rice Milling Machines from Japan’s Leading Manufacturer

Over 100 Years Supporting Rice Producers

Over 100 Years Supporting Rice Producers

As competition for rice sales increases both domestically and internationally, the only way to survive is to increase sales, lower operating costs, and achieve a stable production system.

Our mission is to help you optimize your operations and maximize profitability — all while increasing quality.

Maximizing Profits by Improving Milling Recovery Rate

To grow your operation’s profits, both the drying and milling processes must be optimized. Yamamoto has the expertise in both to provide you with the right equipment and support.

Case Study:

Productivity Boosted,

Costs Lowered

The superior technology, automation capabilities, ease of maintenance, and high durability of Yamamoto machines have helped many rice procedures take their business to the next level.

For example, installing our dryers and milling machines enabled QTR in the Philippines to dry and mill larger quantities of paddy and rice with about half the number of operators and lower energy usage. This resulted in lower overheads and higher milling recovery rate.

Over 100 Years of Excellence in Rice Milling and Drying

When a rice producer installs our dryers or milling machines, they are expected to serve as critical components of their operation for over ten years.

For this reason, we take our role as a manufacturer very seriously. Beyond delivering the best equipment available, we strive to serve as valued partners for the long term.

We have been refining our technology in agriculture and rice milling since 1918. Our grain dryers have held the top market share in Japan for nearly 40 years.

In recent years, our high-performance products and high-quality services have expanded to empower long grain producers worldwide.

Japan’s No.1Batch Circulating Grain Dryers

The top market share in Japan for nearly 40 years

Improve your rice milling business with our grain dryers. They enable rice producers to dry a larger amount of paddy with fewer people and dramatically reduces the need for manual operations.

Our grain dryers’ proprietary design and advanced digital technology automatically optimize temperatures and circulation cycles. Thus, a skilled, experienced operator is not required to produce high-quality, high-milling recovery paddy, thereby boosting profits.

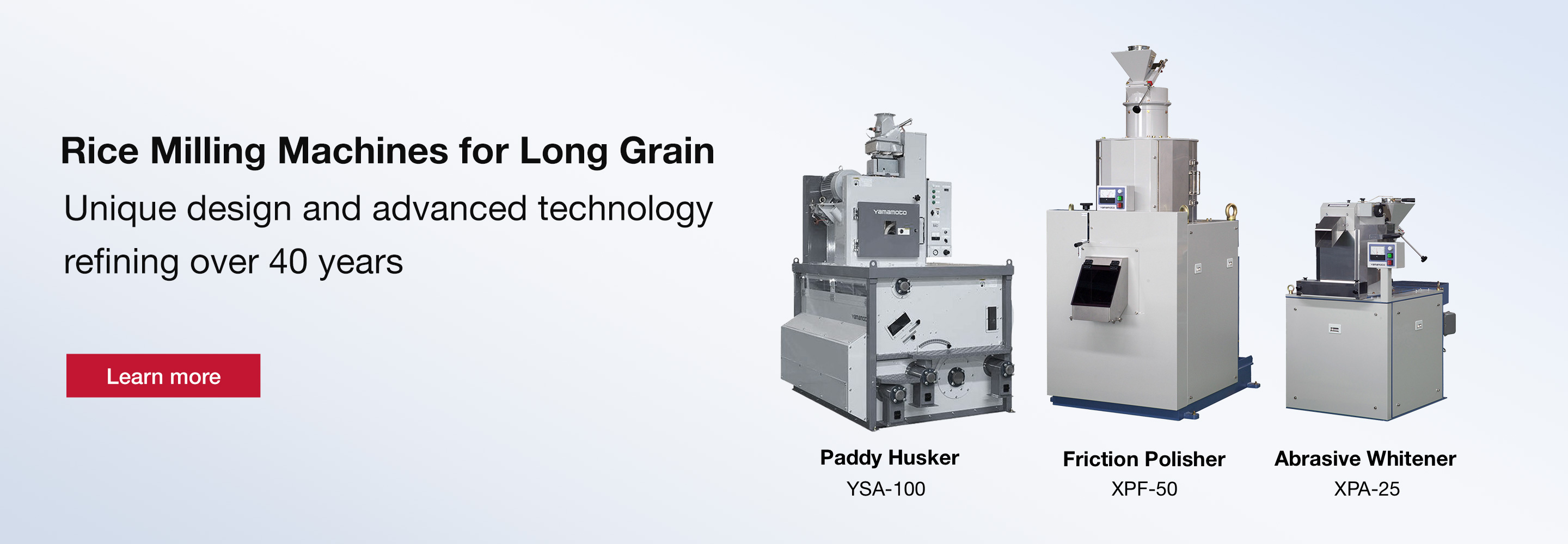

Rice Milling Machines

Unique design and advanced technology refining over 40 years

Our unique design and advanced technology have been refined over 40 years to produce high-quality and high-milling recovery rice with lower electricity costs.

By installing our rice milling machines, you can increase profits while being gentle to your rice and the environment. Especially our unique vertical friction polisher allows the rice to flow naturally by gravity, putting less stress on the rice and using less electricity.

We offer a range of rice milling machines with specs suited to rice variety (short, medium, and long grain), the degree of whiteness required, and the processing capacity.

Contact us today to find the right machine for your needs.

Laboratory Equipment for Rice Quality Control

High precision, active in 30 countries around the world

In the rice milling business, high-precision laboratory equipment are essential for determining quality when purchasing and receiving paddy and measuring recovery rate at the rice mill. Our equipment is compact in design, highly accurate, and is used in 30 countries worldwide.

Several of our products have been certified in the USA and Japan.

Our VP-32T rice milling machine is used for testing by the Japan Grain Inspection Association (Kokken).

Our FC2R-Y test huller is USDA-certified.

News & Events

Notice of Year-end and New Year holidays

2025-12-25

2025-09-25

Notice of Obon (Summer) holidays

2025-07-28

Notice of Golden Week (Spring) holidays

2025-04-15

-

Documentation on dryer and milling machine operation, maintenance, and troubleshooting.

-

Craftsmanship and Sustainability Initiatives

Our mission is to facilitate safe and secure food production worldwide and contribute to sustainable agriculture through superior manufacturing.