Unit Type Whitener XP Series

By incorporating abrasion and friction technology, we improved milling recovery by 0.5 to 1.0% compared to the previous model while enhancing rice quality. The higher efficiency and superior output will contribute to your operation's profitability.

Product Features

High-Quality Milling

We achieve faster processing speeds and high milling recovery rate while maximizing energy efficiency.

Our original abrasion and friction technology are incorporated into an all-in-one rice milling unit. It achieves low-temperature milling while preserving the rice's natural flavor.

With a 20% higher milling capacity over the previous model, the control grinding part exhausts residual rice by air and the turning force of the grinding stone.

Easy Maintenance

You can check the screen section quickly. Daily check ups such as cleaning bran and occasional part replacement are easy.

Large Color Touch Panel

Our XP Series (XP-2500 / 4000 / 5000) feature large color touch panels enabling more straightforward operation and easier checking of rice milling data and maintenance instructions.

Many operations can be performed with a single touch and saved to this machine. This means less time spent training staff and reading cumbersome manuals.

Quiet Operation

The machine runs quietly during milling, thanks to the incorporation of soundproofing into the friction section of the machine's bran removal case. The result is a more comfortable working environment and less stress for the operator.

Customer Stories

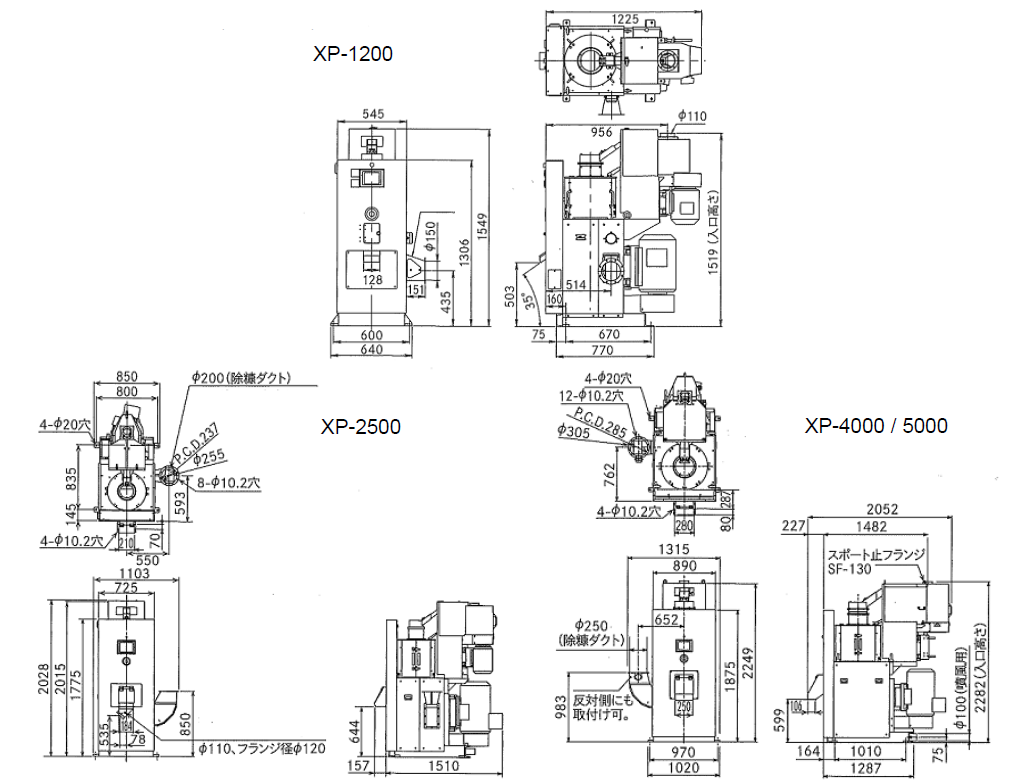

Specifications

| Model Name | XP-1200 | XP-2500 | XP-4000 | XP-5000 | ||

|---|---|---|---|---|---|---|

| Length | mm | 1,225 | 1,662 | 2,052 | 2,052 | |

| Width | mm | 640 | 1,103 | 1,315 | 1,315 | |

| Height | mm | 1,549 | 2,012 | 2,282 | 2,282 | |

| Net Weight | kg | 540 | 1,200 | 1,940 | 1,970 | |

| Max Input Capacity (for short grain) | kg/h | 1,200 | 2,500 | 4,000 | 5,000 | |

| Power | - | 3-phase 200 / 220 / 380 / 420 / 460V | ||||

| Necessary Power | Abrasive | kW | 3.7 (5PS) | 7.5 (10PS) | 11 (15PS) | 11 (15PS) |

| Friction | kW | 15 (20PS) | 30 (40PS) | 45 (60PS) | 55 (73PS) | |

| Fan | kW | 0.4 | 1.5 | 2.2 | 2.2 | |

| Total | kW | 19.1 (25PS) | 39 (50PS) | 58.2 (75PS) | 68.2 (88PS) | |

Options

| Name | Remarks | |

|---|---|---|

| Non-milled rice process system | XP-MS10 | for XP-1200 |

| XP-MS20 | for XP-2500 | |

| XP-MS30 | for XP-4000 / 5000 | |

| Non-residual Air cut Assy | for XP-1200 | |

| for XP-2500 | ||

| for XP-4000 / 5000 | ||

| Power Panel | for XP-1200 | |

| for XP-2500 | ||

| for XP-4000 / 5000 |

Frequently Asked Questions (FAQ)

Answers to frequently asked questions about our rice grain drying and milling machines.

- How do we know which model will best fit our processing capacity requirements?

-

Please get in touch with us with details of your planned processing capacity. We will recommend machines and milling processes to match your needs.

- Can this machine process both short and long-grain?

-

This model is specifically designed for processing short-grain. It is not suitable for processing long grain. Please get in touch with us with details of your requirements, and we will recommend a suitable machine from our lineup.

Inquiry

Please wait a moment for the form to appear.

If the form does not appear, don’t hesitate to contact us via world@yamamoto-ss.co.jp

Product Tours and Consulting

See Our Equipment in Action

Contact us, and we will schedule a tour of the dryer and rice milling machines installed nearest to your location. Please feel free to contact us even if you do not have a plan to purchase.

Free Consulting: Maximize Your Profitability

We have deep expertise in all areas of the rice milling business and have studied many successful operations. Contact us for a free consultation. We’ll share rice production best practices to help your team maximize profit while lowering costs.